If you’re experiencing significant engine problems or unexplained engine noises, you might have a broken or worn rocker arm.

While this isn’t the first thing you should jump to if nothing else is explaining or fixing your problem, a rocker arm might be your problem.

In this guide, we’ll walk you through everything you need to know to diagnose a broken or worn rocker arm before diving into precisely what a rocker arm does and how much it costs to replace one. Let’s take a look at the signs to look for.

Symptoms Of A Bad Rocker Arm

The most common symptom of a bad rocker arm is clicking or ticking noises coming from the cylinder head of the engine. It can also cause misfires or a stalling engine together with a check engine light on your dashboard.

If you suspect that your car has a damaged rocker arm, the chances are that your vehicle is showing some of these signs. Here is a more detailed list of the signs of a bad or failing rocker arm to look for:

1. Clicking or Ticking Noises

If you hear a clicking or ticking noise when you start your engine, a worn rocker arm might be the problem. There are also various other reasons that a clicking or ticking noise might be occurring. Once you’ve ruled out any external causes, you can start worrying about internal issues like a broken rocker arm.

If you hear a clicking or ticking noise and suspect a broken rocker arm, listen to see if the noise is coming from the top of the engine. If it’s a V-shaped engine, the noise will only be coming from one side.

Once you’ve identified the location of the ticking or clicking noise, the only way to verify that it’s a broken rocker arm is to tear apart the top end of the engine and look at what’s going on.

Related: 5 Common Car Engine Noises – Information & Diagnosing

2. Misfires or Stalling

The rocker arm controls the amount of time each intake and exhaust valve is open, so it makes sense that if one of them isn’t functioning correctly, you’ll notice some performance issues. While weaker than normal engine performance is typical, a stalling engine is not.

While it’s certainly possible, most engines can run if one cylinder is misfiring or not functioning correctly. You’ll notice the drop in performance, but if an engine is stalling because of a single worn or broken rocker arm, chances are there’s another problem you’ll need to address too.

Related: Engine Misfire Symptoms & Causes

3. Check Engine Light

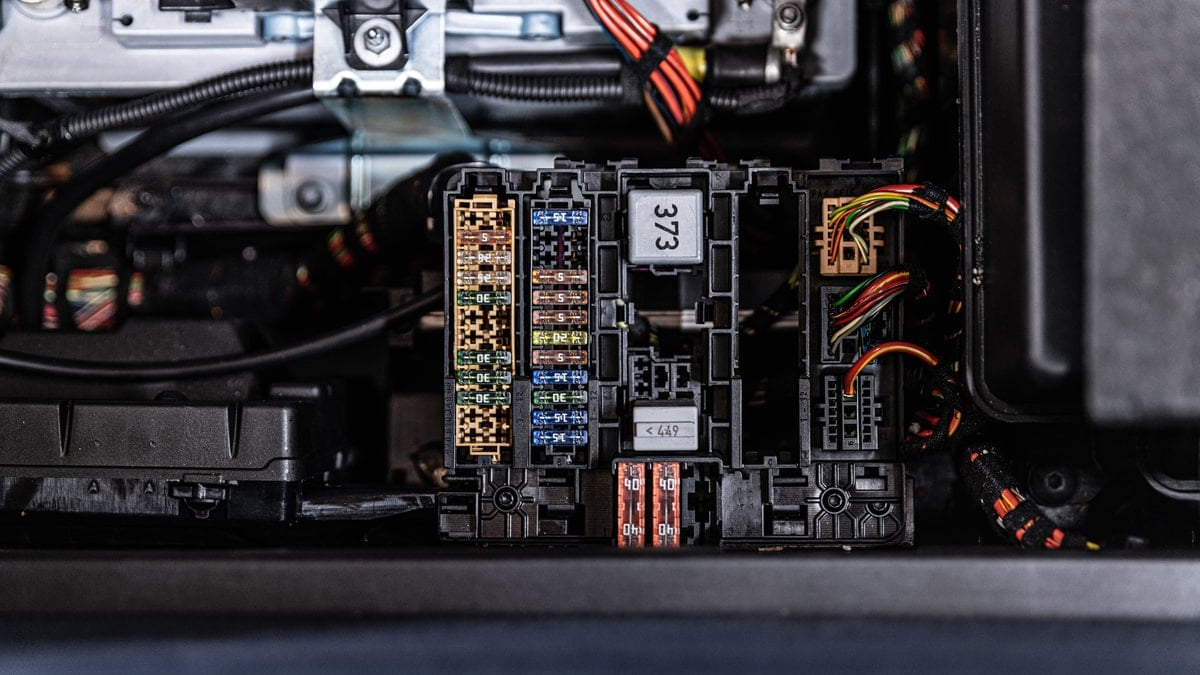

There are tons of sensors monitoring your engine’s performance. Everything gets checked and verified for proper function. So, while there’s no sensor for each rocker arm, the decreased engine performance can easily lead to a check engine light.

The exact code on that light will vary because the broken or worn rocker arm’s side effect tripped it, not the rocker arm itself. That’s not to say that the code won’t mention a rocker arm – it definitely can – but it might point you towards an actuator or a switch when that’s not necessarily the problem – but it could be!

Related: Flashing Check Engine Light: Causes & Solutions

4. Physical Deterioration

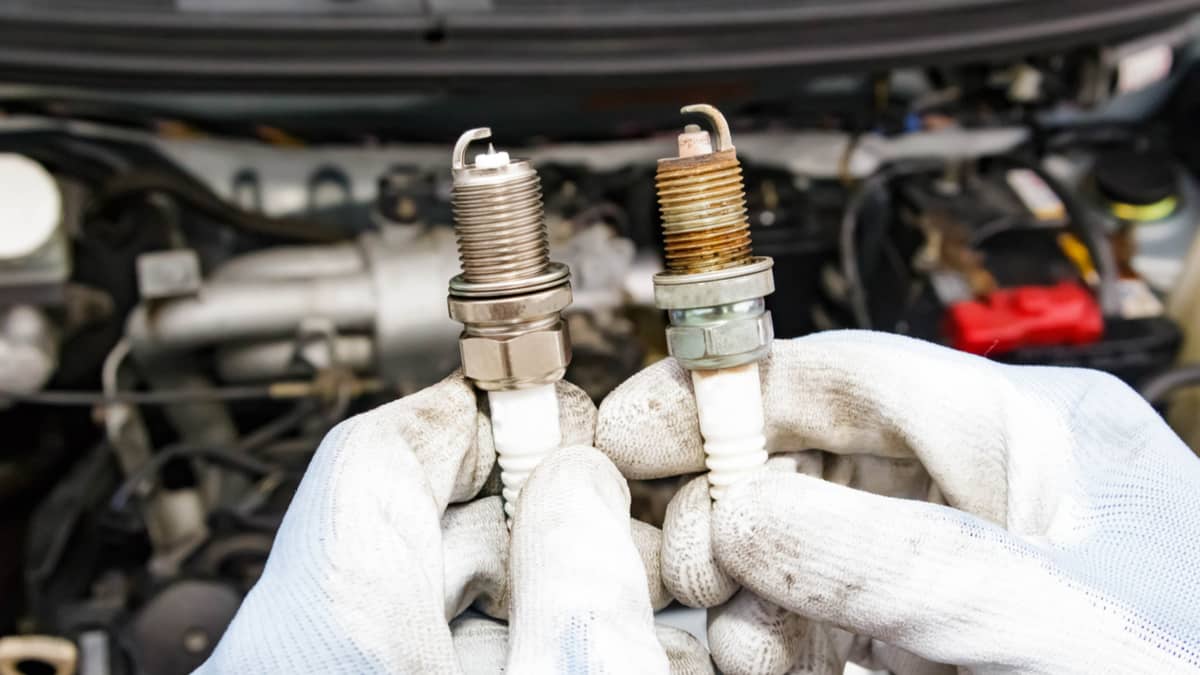

Once you suspect a broken or worn rocker arm, the only way to 100 percent verify that the rocker arm is the issue is to remove the valve covers and see what’s going on underneath. If your vehicle has worn rocker arms, you’ll notice excessive play or metal underneath the rocker arm. If the rocker arm is extremely damaged, you might even find a cracked rocker arm.

If you’re not sure, compare the rocker arms against each other – they should all look the same. If any rocker arm shows signs of wear or damage, you should replace them all.

The Function of a Rocker Arm

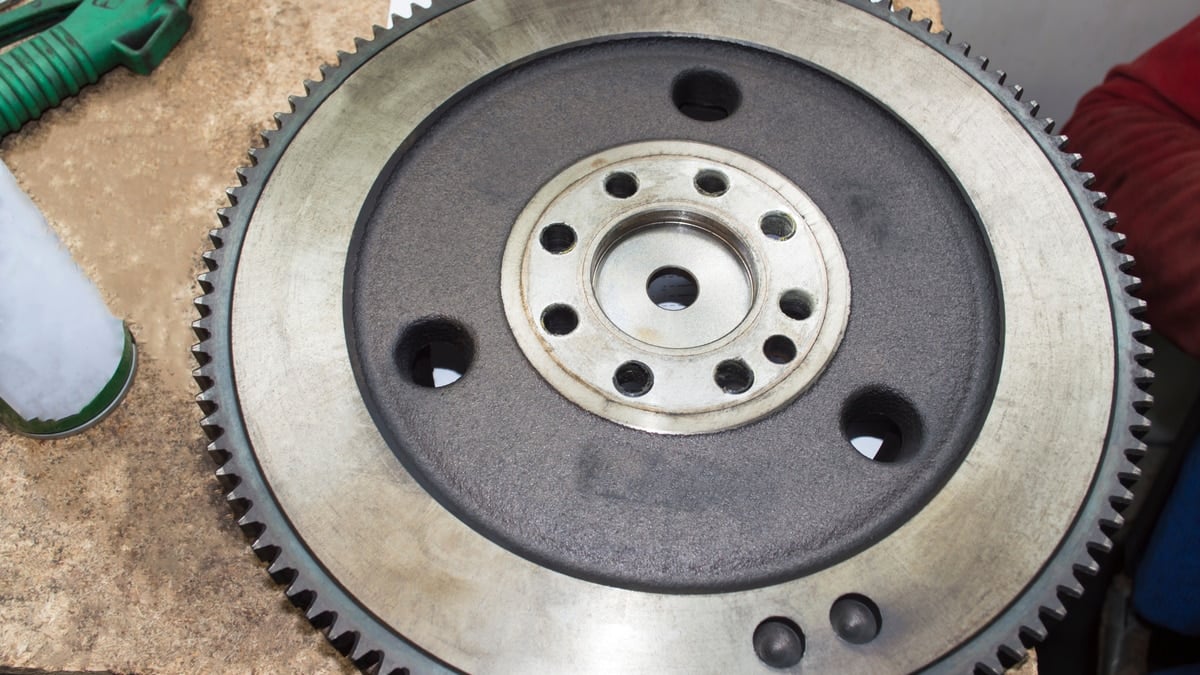

While most people don’t think of rocker arms, they’re a critical and central part of your engine. The rocker arms lift your exhaust and intake valves to allow air to enter and exit the combustion chamber at the appropriate time.

In purely mechanical turns, the rocker arms transfer the vertical reciprocal motion from the pushrods to the exhaust/intake valves.

It might not sound like much, but without these little contraptions in your engine, you wouldn’t start, and you wouldn’t get any air into or out of the combustion chamber.

Some engines do not have rocker arms. Instead, the camshaft pushes directly on the hydraulic lifter, which is then pushed directly on the valve.

Rocker Arm Location

The rocker arms are located at the engine head, connecting the camshaft to the exhaust and intake valves.

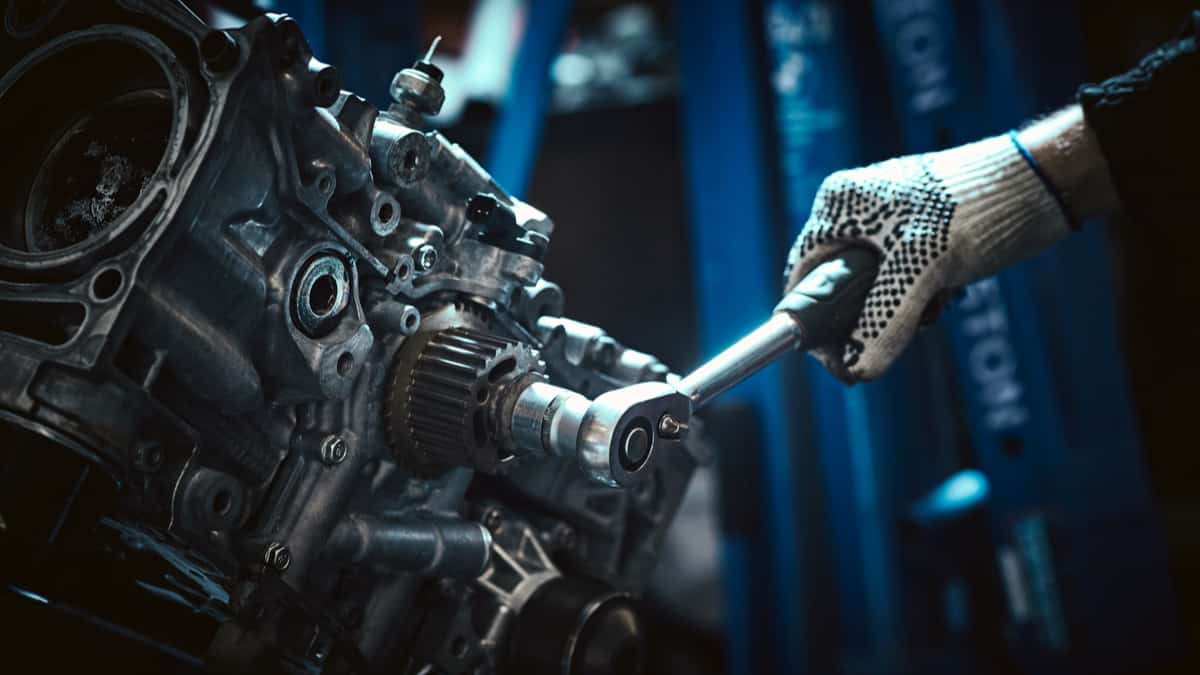

When you look at your engine, you’re not going to see the rocker arms. That’s because they’re underneath the valve covers that are positioned directly over the engine’s heads. Furthermore, they’re located directly between the engine’s pushrods and the intake and exhaust valves.

While it’s easy to point to where a rocker arm is, actually seeing and accessing the rocker arms is far more complicated.

Rocker Arm Replacement Cost

The average single rocker arm replacement cost ranges from $500 to $1,500, and almost all of this cost is for labor. In fact, each rocker arm typically costs between $5 and $20. But that’s not the only parts you’ll need.

Because to reach the rocker arms, you’ll need to remove the valve covers and various other components, so you should replace all the gaskets associated with them too. You’ll also end up draining the oil, so you should throw a filter in there as well.

But even with all of those factors thrown in, the parts should still only cost you around $100 to $150 – all the rest is the cost of labor. That’s a large part of the reason you should replace all of your rocker arms at the same time.

They tend to wear out at a similar rate, and since most of the work the mechanic already did most of the work by accessing the rocker arms, throwing in a few extra rocker arms doesn’t cost you another $500 to $1,500 each. As long as they’re under the same valve cover, you’re probably only looking at an extra $10 to $25 for each additional rocker arm.

If you have to remove the other valve cover gasket to reach the additional rocker arms (like in a V-shaped engine), this cost will be slightly higher, but it’s still worth the initial investment to save you some money down the road.

But just because most of the cost is in labor doesn’t mean you should attempt to complete this repair yourself. That’s because it’s a labor-intensive process that requires a lot of technical know-how. Doing the job the wrong way can be more detrimental than not doing it all.

Luckily, rocker arms do not get damaged or worn so often that they need a replacement. The hydraulic lifters control this wear. Most rocker arms also have adjustments if they become worn, but you do definitely have to replace it if one is getting damaged.

Categories: Engine