Engine compression relates to how much pressure is generated by the engine within the cylinders while it’s on. The amount of pressure produced by the engine determines the power and efficiency. If there’s low engine compression, you’ll start to notice performance issues, which is why it’s imperative to fix them immediately.

In this guide, we cover the top causes of low engine compression. We also discuss some of the main symptoms and show you some ways to fix the compression issue. At the end of our article, you’ll find some relevant questions and answers related to engine compression.

What Could Cause Low Engine Compression?

Low engine compression usually comes from leaking valves or valve seats, damaged piston rings or worn pistons. It can also be caused by faulty hydraulic lifters, the wrong camshaft timing, a damaged head gasket, cracked cylinder walls, or a too-rich fuel mixture that’s washed the cylinder walls.

Let’s look at each of these possibilities a little more in-depth.

1. Leaking Valves Or Valve Seats

On top of the cylinder, you find valves. There are both intake and exhaust valves that are needed for the engine to run. The intake valve is responsible for taking in the fuel and air to use during combustion. All of the gases formed from this process exit through the exhaust valves.

When valves get too hot, a hole can form, and they can leak compression. Additionally, the seats can wear down over time, allowing the gas to escape. This common problem creates low engine compression.

2. Worn or Damaged Piston Rings

An overheating car engine can cause the rings of the piston to become warped and damaged. When this happens, gases leak through the damaged seal.

Piston rings can last for the lifetime of the engine if the car is cared for. When they become worn or damaged, however, low compression occurs until the leak is repaired.

RELATED: 4 Symptoms Of Piston Rings and Replacement Cost

3. Worn or Damaged Pistons

Moving beyond the rings, there’s also the threat of something happening to the pistons. The majority of pistons are made from aluminum alloy, so they should handle the everyday combustion needs of an engine. However, overheating can cause them to warp.

In some cases, areas can become so hot that holes burn through the piston. If this happens, there’s no way to keep the gases from escaping through the holes, which creates low compression.

4. Faulty Hydraulic Lifters

Hydraulic lifters are cylindrical in shape, with an internal piston protruding from the top. They are installed between the valves and the camshaft. Once upon a time, solid lifters were used that required adjusting, but hydraulic lifters are self-adjusting. There should always be play between the camshaft and lifter because of the oil that’s used to control movement.

Once the engine gets a lot of miles on it, the lifters begin to wear out. When this occurs, the lifters can no longer hold the right amount of oil pressure, leading them to compress when the camshaft opens. The valves don’t open correctly when this occurs, leading to low or no compression.

RELATED: 4 Symptoms Of A Bad Hydraulic Lifter

5. Wrong Camshaft Timing

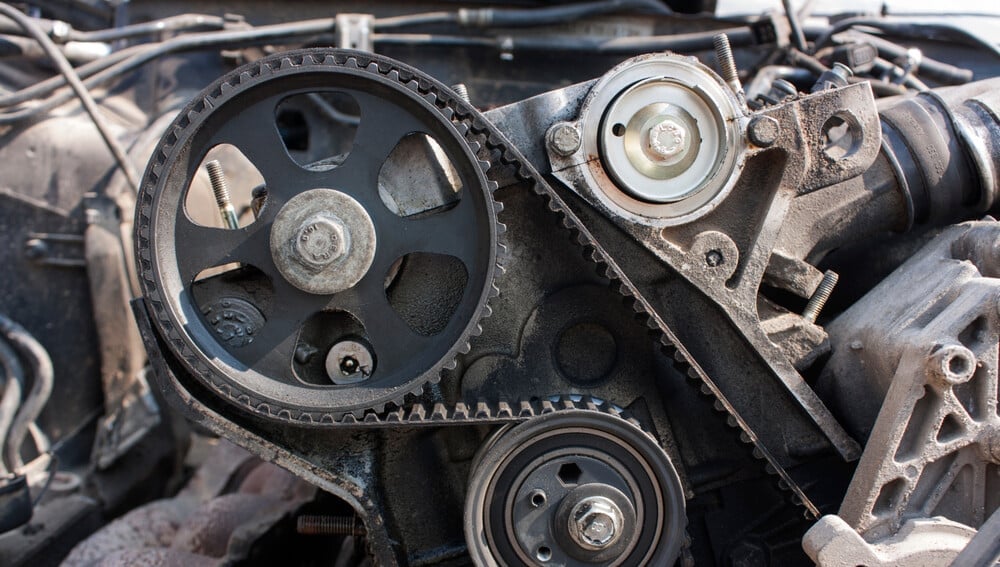

When there’s low compression across all of the cylinders, it’s most likely caused by a faulty timing chain or belt. It’s also possible that the belt or chain wasn’t installed correctly, leading to incorrect camshaft timing.

From the crankshaft’s rotation, the chain or belt transfers power to the camshaft, so the valves can be opened at the appropriate time. These valves are responsible for transferring gas coming in and out of the engine, so it’s important that everything is timed right.

If the timing is off, the valves can fail to release or inject the gases when they should be. This can cause low compression across all cylinders.

However, in more severe cases, the valves will hit the pistons. This action causes the valves to bend and create no compression, so you won’t be driving anywhere until it is repaired.

6. Worn or Damaged Head Gasket

At the top of the engine, there’s a gasket installed. It’s found at the cylinder head. An overheating engine can cause this gasket to fail. When this happens, a hole is left between the head and the cylinder.

You may have heard the term “blown head gasket,” which refers to this condition. With a blown head gasket, the engine suffers from low compression. It can also cause the oil and coolant to mix.

7. Cracked or Damaged Cylinder Walls

Pistons are continuously running within the cylinders. To have the rings seal correctly, the surface of the cylinder walls must be optimal. However, debris can be sucked into the engine leading to damage to the cylinder walls.

There’s also the chance that the cylinder walls will crack or break, especially as the engine gets older. Either one of these problems can lead to low compression.

8. Washed Cylinder Walls By A Rich Fuel Mixture

Cylinder walls are lubricated by oil that’s dispersed from the crankshaft as it rotates. If the car starts running rich because of a failed sensor, the gasoline can wash the oil away from the cylinder walls.

Without this oil on the cylinder walls, compression can be low. Normally, this isn’t the most prominent cause, but it is possible.

How To Fix Low Engine Compression

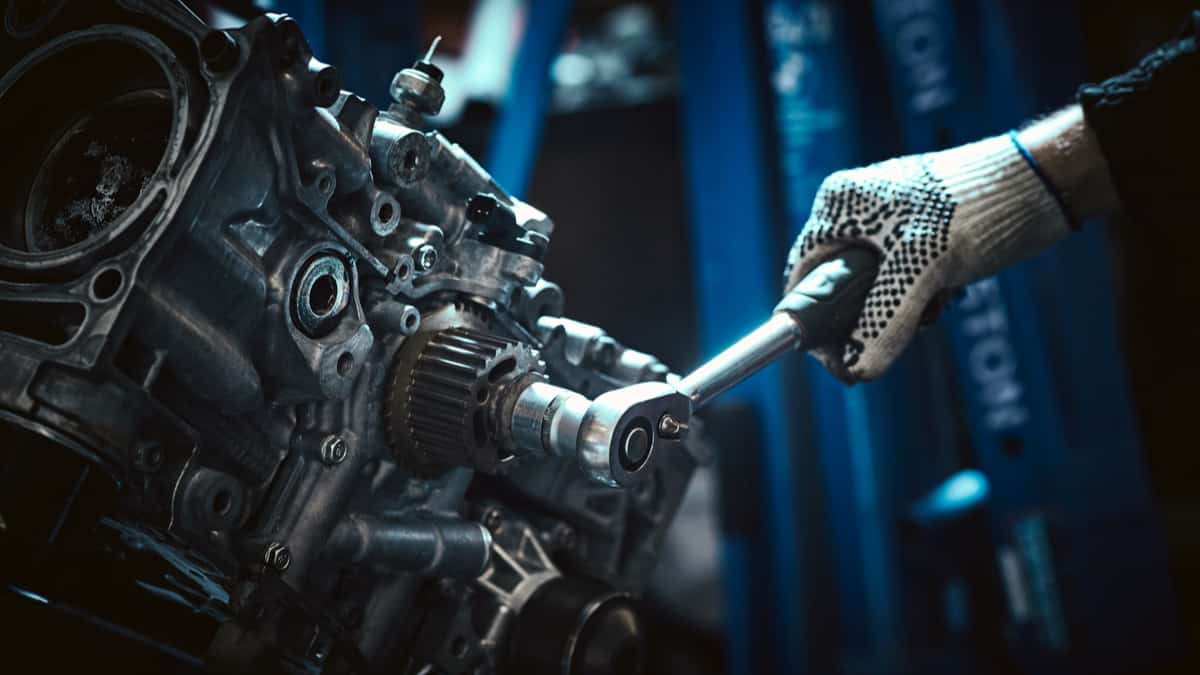

You don’t always have to be a professional mechanic to fix low engine compression, but you will need some special tools. Additionally, these tactics aren’t as simple as your regular oil change, so you want to have some expertise to pull from. Here are some steps to consider.

1. Check Camshaft Timing

If you notice low compression on all of the cylinders, you want to start by checking the timing chain or belt. Inspect the belt or chain for any signs of damage. Replace it if it looks worn.

Otherwise, you can continue to check the camshaft timing. However, some of the techniques needed are on the advanced side, so you may want to move to step five for more help.

2. Add Some Oil to the Cylinder with Low Compression

If there’s low compression on one cylinder, you can put some oil into it and retest. If higher pressure occurs after putting oil into the cylinder, you know where the problem lies.

The underlying issue may have to do with a misfiring engine, which should be resolved. Also, the piston rings may not be sealing correctly, which also requires a repair.

3. Remove Oil Cap and Look For Blow-By

You must be very careful when doing this step as the engine oil can be very hot and dangerous. Carefully open up the cap while the engine is running.

If you are able to feel overpressure occurring and see smoke, there’s compression leaking through the pistons and getting into the crankcase. In this case, you may need to repair a crack or replace the rings or piston. When everything is working correctly, there’s going to be a lack of pressure in the crankcase while the engine is idling.

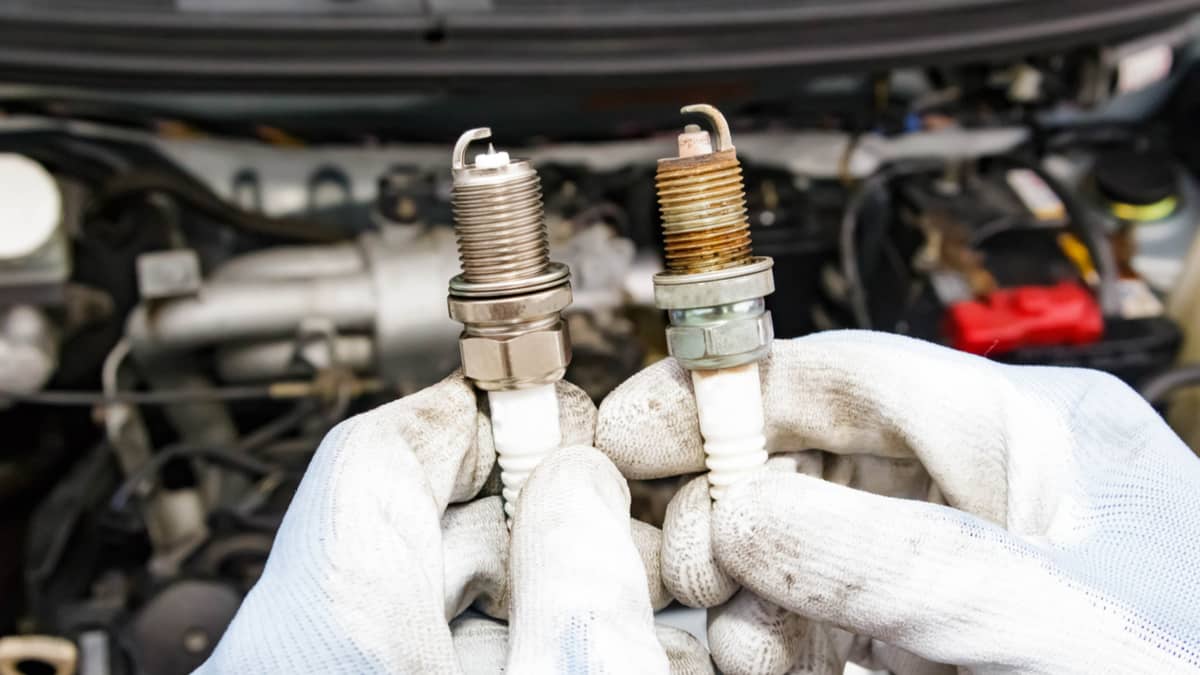

4. Leak-Down Test

With a leak-down tester, you can see where the compression is leaking. Connect the pressure gauge in place of the spark plug, so the positive pressure can be read.

It’s important that the valves are closed when the pressure is put into the cylinder. You want to listen for leaking compression coming from the crankcase ventilation or the valves, either intake or exhaust.

5. Contact A Professional

These are not simple problems to figure out. For that reason, most home mechanics are going to prefer having a professional help with the compression issue.

Find a qualified mechanic in your area to take your vehicle. The amount of time it takes a professional to fix the problem will be much faster than most novices can perform, especially if you don’t have the right equipment.

What Are The Symptoms Of Low Compression?

Compression is needed to ensure maximum engine performance. With low compression, the engine is going to lose power. This power loss can cause misfiring and jerking movements while driving. The problem will be directly related to how many cylinders are suffering from low compression. For example, a lack of compression in one cylinder won’t be as troublesome as if all four have low compression.

Because the engine isn’t running correctly, you’ll also notice a drop in fuel economy. You may need to visit the fuel pump more frequently during this time. In severe situations, the car may no longer start. With low compression, there’s not enough pressure to ignite the air-fuel mixture that’s needed to get the engine going. You are also likely to see a check engine light on your dashboard, with misfiring trouble codes stored.

Is it OK to drive a car with low compression?

You can but shouldn’t. At best, the car is going to run rough and create an unsafe situation on the road. While you may still be able to drive, you have no way of knowing how the vehicle will respond. Additionally, the car could stop running at any time, so we recommend having the problem fixed immediately.

What does low compression in an engine mean?

The problem could come from the valves, valve seats, piston rings or pistons. It could also be due to faulty hydraulic lifters, a blown head gasket, poor camshaft timing or cracked cylinder walls. While less likely, it’s also possible that the cylinder walls have been washed clean with a rich fuel mixture.

Is it expensive to fix low compression in an engine?

It depends on what the problem is. A timing belt replacement may cost between $400 and $1,250, while a blown head gasket can regularly cost $1,500 to $2,500. It’s important to get a professional diagnosis to avoid replacing unnecessary parts.

Can an engine regain compression?

Most problems are only going to continue getting worse until they are repaired. However, there are some products that claim to restore the cylinder walls with the right amount of oil, which could help you regain some compression. For the cost, it’s worth trying before getting an expensive repair.

Dealing with low engine compression can be troublesome. It’s natural to feel confused and overwhelmed because the problem is severe. This isn’t something that can usually be dealt with quickly, so some time and patience will be required. However, with the right tools and some time, you can get to the bottom of what’s causing the low compression, so it can be repaired.

We highly recommend having a professional look at your vehicle if you aren’t familiar with low compression. Working with engines can be tricky and you don’t want to cause any further damage. After all, you don’t want an already expensive $1,000 repair turning into a need for a new car engine.

Categories: Engine, Troubleshooting