Modern vehicles are equipped with many advanced sensors designed to ensure optimum performance. One example is the DPFE sensor, which is part of the EGR system in many Ford cars.

If your vehicle is experiencing symptoms of a bad DPFE sensor, it can become difficult to drive and create an excessive amount of air pollution.

I look at the top symptoms you might notice when the DPFE sensor fails. I will also show you where it is located, and help you understand this part’s vital function. In the end, I discuss the cost of replacing the DPFE sensor and the difficulty of the job. Let’s begin with a quick look at the symptoms.

What Are The Symptoms Of A Bad DPFE Sensor?

The main symptoms of a bad DPFE Sensor include:

- Poor engine performance

- Reduced fuel economy

- Failed Emissions Tests

- Check engine light

Here is a more detailed list of the signs of a bad or failing DPFE sensor to look for:

1. Poor Engine Performance

When the DPFE sensor fails, the engine can’t run as it was designed to. In fact, engine performance issues are the first sign that something is wrong with this sensor.

With a faulty sensor, the wrong information is sent back to the engine’s computer. Because of this bad data, the EGR system malfunctions. With this system not running properly, you will notice reduced power and a rough idle.

2. Reduced Fuel Economy

For your vehicle to receive the EPA-estimated fuel economy numbers, everything must be running perfectly in the engine. With a failed DPFE sensor, that isn’t going to happen.

With the computer receiving the wrong information, the motor is going to work harder to compensate for the faults. This extra effort requires more fuel, which is why you might start spending more time at the gas station.

3. Failed Emissions Tests

The DPFE sensor is required for a well-running EGR system. When the EGR system isn’t running as it should, the vehicle will fail an emissions test.

Every state has laws about emissions tests, often required for registration. If your vehicle can’t pass the emissions test, you might have trouble driving legally. You are also contributing to more pollution in the environment.

4. Check Engine Light

When the computer system recognizes a problem, the Check Engine Light comes on. In this case, the fault is related to a malfunctioning EGR pressure sensor signal.

However, a Check Engine Light alone doesn’t indicate a faulty DPFE sensor. In fact, this light comes on whenever there is a problem with the motor. The only way to know for sure is with an OBDII code scanner.

Ford DPFE Sensor Function

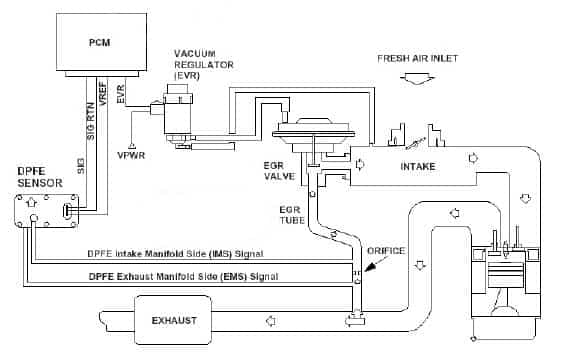

The DPFE sensor stands for Differential Pressure Feedback of EGR. It’s also called the Delta Pressure Feedback of EGR because “Delta” means change. In all situations, the DPFE sensor is used to monitor the pressure changes of the EGR system.

The EGR system is the Exhaust Gas Recirculation system. It is the process used to suck exhaust gas back into the motor so it can burn again. This modern technology helps to reduce pollutants coming from the vehicle.

When the gases come through the EGR tube, the two tubes that attach to the DPFE sensor are pressurized. The DPFE sensor determines the difference in pressures between the two tubes to determine how much gas is flowing through the system. This information is then sent to the PCM so the actuator can be controlled better, allowing the proper amount of gas through. Without the DPFE sensor, the wrong information is sent, leading to an imbalance of the exhaust gases.

You will find the DPFE sensor in Ford engines like the ford ranger, expedition, taurus, escape, focus, and many more. You can also find it in some Lincoln cars.

DPFE Sensor Location

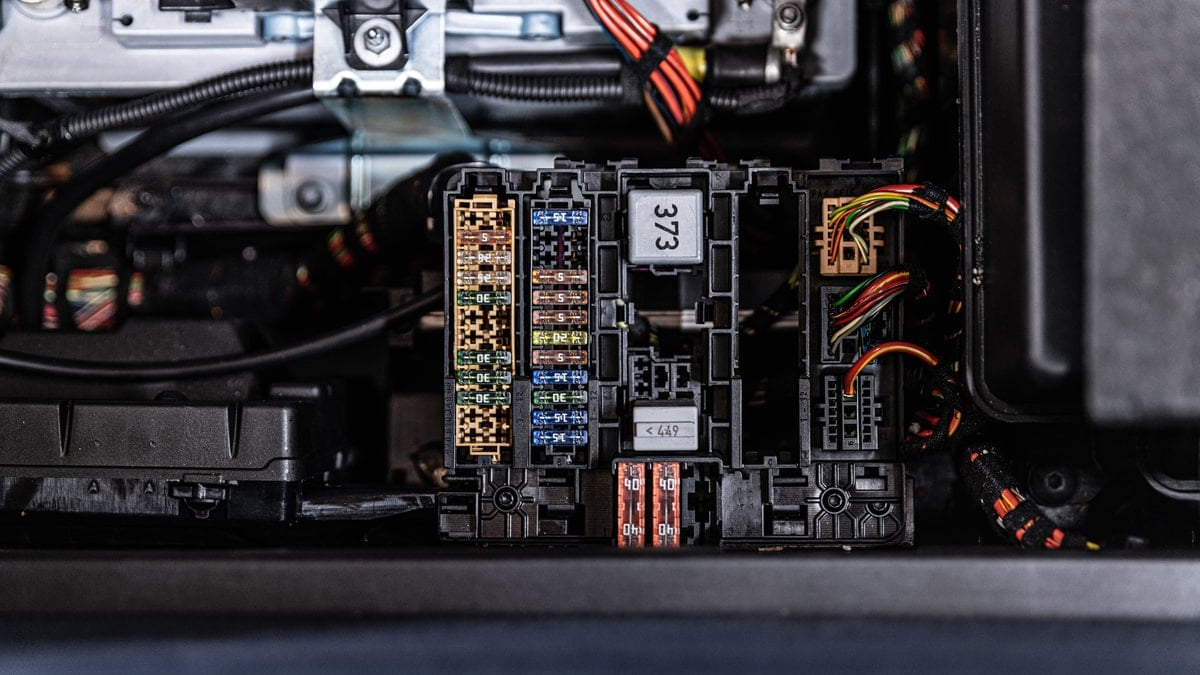

The DPFE sensor is often located near the EGR valve. This valve is found behind the upper intake manifold, which is between the motor and the firewall.

The DPFE sensor is often shaped like a small square. You will see two vacuum hoses attached to the bottom, and there is a wiring harness coming from its side.

However, the exact location can vary based on what model vehicle you drive. Therefore, it’s best to consult your service manual for a diagram and the exact location.

DPFE Sensor Replacement Cost

The cost to replace a DPFE sensor and EGR valve range from $150 to $500. The parts tend to make up the majority of the cost, usually between $100 and $400, while the labor might only be $50 to $100. However, replacing the DPFE sensor is a simple task that can be done with a few everyday tools.

You shouldn’t drive with a faulty DPFE sensor. If you are noticing a rough idle or a lack of engine power, it’s best to replace the DPFE sensor and EGR valve. Leaving the car with a faulty EGR system only causes trouble passing emissions tests and leads to further air pollution.

How do you check a Ford DPFE sensor?

You can use an ordinary multimeter to check the DPFE sensor in your Ford and see if it is malfunctioning. Start by locating the sensor, which is somewhere near the EGR system, and back-probe the signal pin. Then, set the multimeter on DC Volts, turn on the ignition, and measure the voltage. You should see approximately 5 volts, with anything significantly different suggesting a defective DPFE sensor. Additionally, you can carry out a resistance test when the ignition is off, with expected values ranging from 150 to 300 ohms.

What does the DPFE sensor do?

The DPFE sensor measures the gas flow through a pipe connecting the exhaust and the EGR system. It does this by measuring the pressure before and after the orifice inside the pipe. Based on this data, the PCM assesses the flow through the EGR system and, when needed, regulates it with an EGR control valve. This system is most commonly used in Ford’s vehicles with Modular gasoline 4.6 and 5.4-liter V8 engines.

How do you know if the DPFE sensor is bad?

A faulty DPFE sensor will likely trigger a check engine light, meaning there will be a corresponding error code in the vehicle’s memory. Some codes you may expect to see if this is the case include P0401, P1401, or P1406. In addition, you may experience rough idle, stalling, and poor fuel economy. Moreover, your car will likely fail its emission test. But before blaming this on the DPFE sensor, you should first check the connector, wiring, and the EGR system itself. Sometimes, the pipings and hoses may be clogged up with soot, which completely blocks the flow of exhaust gases.

What would cause a DPFE sensor to melt?

Several things can cause the DPFE sensor to melt, and an internal electrical malfunction is one of them. This may cause increased resistance or short circuit, which heats up the sensor and melts it if the temperature becomes high enough. The same might happen because of heat exposure if the DPFE sensor is installed too close to the exhaust. Lastly, the EGR system, if clogged, may become too hot and melt the surrounding components.

Most modern cars have an EGR system, which is short for Exhaust Gas Recirculation. This emission-control device returns the portion of burnt gases back into the engine to reduce the exhaust’s NOx content. But because the system may clog up with soot buildups, the flow of gasses through it is monitored.

Most Ford models made in the early 2000s use a DPFE system, which is short for Differential Pressure Feedback of EGR. It uses a sensor to measure pressure differences at different points of the EGR system, which is then used to assess the flow. This sensor and connecting hoses may fail, which can result in incorrect readings and engine running issues.

Categories: Engine