Modern vehicles are jam-packed with sensors that keep everything operating the way it should. But while all these electronics create far more efficient and powerful vehicles, they can also create massive headaches when something goes wrong.

One of the most critical sensors in your vehicle is the crankshaft position sensor. But what does this sensor do, where you can find it, and how much does it cost to replace it? We’ll answer all those questions and more in this comprehensive guide. Let’s take a quick look at the common symptoms first.

Symptoms Of A Bad Crankshaft Position Sensor

The most common symptom of a bad crankshaft position sensor is a check engine light on your dashboard. You will often also experience a stalling engine or bad engine performance. In rare cases, you will also notice engine vibrations or misfires.

But while these are the most common symptoms, they aren’t the only signs that can point you toward a faulty crankshaft position sensor. We’ll take an in-depth look at the signs of a bad or failing crankshaft position sensor to look for:

1. Check Engine Light

As I said before, the most common symptom of a bad crankshaft position sensor is a check engine light. The good news is that if you have a check engine light, then your ECM has reverted to default measurements.

While this might cause a few performance issues, it should help prevent further damage from occurring. However, the longer you leave the problem unaddressed, the worse it will become.

2. Excessive Engine Vibrations

If your engine has a faulty crankshaft position sensor, then it isn’t optimizing any performance. Even worse, it might be utilizing incorrect readings to determine fuel and ignition timing. If the ECM doesn’t time things correctly, you’re in for a bumpy ride.

Even worse, the problem is only going to get worse until you fix it, and it’s only a matter of time until further damage occurs.

3. Reduced Engine Performance

Whether you have a check engine light or not, a faulty crankshaft position sensor will lead to reduced engine performance. Whether it’s default values or the wrong values entirely, anything less than optimal timing is going to reduce your overall performance.

Top speed and acceleration are the two most significant areas in which you are going to see a reduced performance.

Keep in mind that an engine that isn’t performing correctly is also going to have a reduction in fuel economy, but unless you’re paying close attention to how many miles you get out of each tank, you might not notice.

4. Difficulty Starting Your Vehicle

If your defective crankshaft position sensor is extremely out of sync, you might have trouble getting your vehicle started. Furthermore, you might have difficulty keeping it started.

This is usually only a problem when the problem has persisted for some time, and you likely have multiple other underlying issues too. Moreover, it’s not usually a problem if you have a check engine light and the ECM has defaulted to predetermined values.

Instead, it’s a problem when the crankshaft position sensor is feeding inaccurate readings and your ECM doesn’t realize it.

5. Engine Stalling

While this indicates a severe fault, it’s possible that a faulty crankshaft position sensor could lead your vehicle to stall. This happens when the ECM is sending all the wrong fuel and ignition timing to each cylinder.

Typically, it will take a while for a problem to get this bad, and if it is, there’s a good chance there’s further damage that you’ll uncover after you replace the crankshaft position sensor.

6. Engine Misfires

While it’s unlikely that a vehicle with a check engine light on will misfire, if the ECM uses incorrect positions of the crankshaft, it becomes incredibly likely. Even worse, if you have an engine that’s misfiring, it’s only a matter of time before engine damage occurs.

The longer you let a misfire happen, the worse it’ll get, and the more expensive the eventual repairs will be. If you have a misfire, get repairs as soon as possible.

RELATED: 6 Symptoms of an Engine Misfire

Crankshaft Position Sensor Function

The purpose of the crankshaft position sensor is to measure the position of the crankshaft. It might sound redundant, but it’s one of the most critical sensors in your vehicle. The crankshaft position sensor sends these measurements to the ECM, and the ECM uses them to optimize the rest of your vehicle’s timing.

If the crankshaft position sensor fails, then the ECM reverts to default values. While these values keep the engine running, you’ll likely notice various performance issues.

However, if the ECM doesn’t realize that the crankshaft position sensor has failed and is sending it errant measurements, the computer will optimize performance to inaccurate readings. This can quickly lead to more damage and expensive repairs.

Crankshaft Position Sensor Location

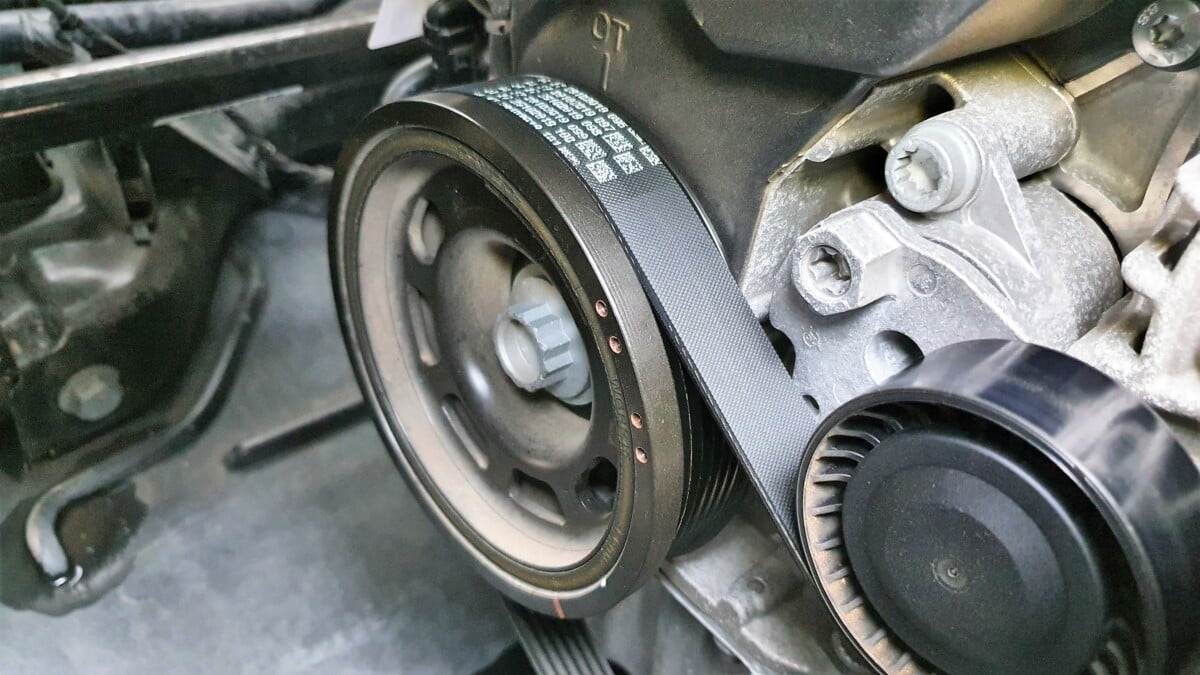

Your vehicle’s crankshaft position sensor is located near the bottom of the engine by the crankshaft. That makes sense because it’s the crankshaft position sensor’s job to measure the crankshaft location.

When you’re trying to track down the crankshaft position sensor, look towards the engine’s bottom, generally on one of the sides. Since the sensor is so far down in the engine, it can be hard to locate and even harder to remove and replace if you have a faulty one.

Crankshaft Position Sensor Replacement Cost

The average crankshaft sensor replacement cost is between $150 and $250. However, it’s not uncommon for those prices to skyrocket if you have a higher-end vehicle.

That’s because the labor costs are typically between $90 and $110. From there, the rest of the cost comes down to parts. While most crankshaft position sensors cost under $100, there are a few out there that can blow through that price point.

Fortunately for most drivers, those more expensive parts are typically only on high-end luxury vehicles. If you’re looking to save a few bucks, you can replace the sensor yourself. It’s a pretty straightforward job if you can reach the sensor.

While this is only going to save you about $100, if you’re a little mechanically inclined, you can complete the entire job in under 30 minutes.

It is rare, but there are actually some car models where the sensor is located behind the flywheel, and if this is the case, you will have to remove the gearbox to replace the sensor.

Don’t forget to diagnose and test the crankshaft position sensor before replacing it.

Can you run a car without a crankshaft position sensor?

Your car engine will most likely not run without a crankshaft position sensor. If your car’s crankshaft position sensor goes bad, the engine may not start because it won’t be able to tell when the spark plugs should fire. However, if your car uses camshaft position sensors, it is possible that the ECM will use these instead of the crankshaft position sensor. So in this case, your car could potentially run without the crankshaft position sensor.

Will disconnecting the battery reset the crankshaft sensor?

No. The crankshaft sensor is located on the engine block and measures the position of the crankshaft. It can’t be reset by disconnecting the battery because there is no data stored to be reset. In most car models, you need to use an OBD2 scanner to clear the ECM’s trouble codes.

How long do crankshaft sensors last?

There is no definitive answer to this question as the lifespan of a crankshaft sensor depends on a number of factors such as driving habits, sensor manufacturer, and the overall condition of the vehicle. Crankshaft sensors are built to last the life of the car, and should only be replaced if they are bad.

Can a crankshaft sensor be cleaned?

Yes. A crankshaft sensor can be cleaned. Just be careful not to damage the sensor when cleaning it. However, just cleaning the sensor probably won’t do much to fix it, but if the sensor’s connector pins are corroded, it might help to fix the sensor.

Categories: Engine