Unless you are a mechanic, you may never have heard of a crankshaft pulley nor understand what it does. You certainly wouldn’t know the symptoms of a bad crankshaft pulley unless you started looking into it after having some trouble.

In this guide, we break down the top bad crankshaft pulley symptoms you may encounter. We also look together at the purpose and location of the crankshaft pulley, as well as examine the replacement costs. Once you reach the end, you’ll have some of your most important questions answered.

Symptoms Of A Bad Crankshaft Pulley

When the crankshaft pulley goes bad, it leads to engine vibration, a stalling engine, a car that won’t start and an irregular engine idle. It can also keep the battery from charging, cause a loss of power steering, overheat the engine and ultimately lead to transmission or internal engine damage.

Some of these symptoms are more common than others, but all of them are possible. Evaluate these top symptoms closer.

1. Engine Vibration

The car engine vibrates excessively from all of the movement occurring inside, but designers have worked hard to find ways that minimize the shaking. One way that this is accomplished is through the harmonic balancer that’s attached to the crankshaft pulley.

If the pulley is bad, the engine vibrations naturally increase because there’s nothing absorbing them. You may notice this problem more when the engine revs up higher. Continuing to let the engine vibrate like this only leads to further damage.

2. Stalling Engine

It’s not a common occurrence to deal with a stalling engine when the crankshaft pulley goes, but it can happen. When the crankshaft pulley no longer spins the serpentine belt, you’ll have trouble keeping the motor going.

Some vehicles read the engine speed from the crankshaft pulley teeth with a crankshaft position sensor, and if this pulley is bad, the engine will stall.

Before this happens, you should notice some of the other symptoms. For example, there would need to be a decent amount of vibration occurring for the serpentine belt to jump in the first place. Hopefully, you take action before it gets this far.

3. Car Won’t Start

This problem goes hand-in-hand with the last one. If the crankshaft position sensor can’t read the engine speed from the crankshaft pulley’s teeth, you may not be able to start the engine.

This can also come because of a dead car battery because the alternator failed to work. Of course, you should have noticed some battery issues before it gets to this.

4. Irregular Engine Idle

Even with engine running as it should, the crankshaft pulley endures a lot of tension. When the crankshaft pulley fails, everything gets out of balance.

You may notice a rough idle as a result of the failure. It’s also possible that the crankshaft position sensor is not reading the engine speed properly from the bad crankshaft pulley and that can therefore result in irregular engine idle.

5. Battery Not Charging

The car alternator is responsible for charging the battery while the engine is running. It also provides power to the accessories.

When the crankshaft pulley fails and there’s a problem with the serpentine belt, the alternator won’t be able to run. Therefore, power will no longer be supplied to the battery or the accessories. You may end up with a dead car battery as a result of the failure. Yet, a battery warning light should come on the dashboard to tell you there’s no charge occurring.

6. Loss Of Power Steering

The crankshaft pulley is responsible for supplying energy to the power steering pump through the serpentine belt. This pump needs to circulate hydraulic fluid into the steering system, so you have help maneuvering the vehicle.

If the serpentine belt can’t run the power steering pump, you will lose the added boost. It can become quite difficult to steer a vehicle without this system, causing you to possibly lose control. However, this same symptom can be caused by low power steering fluid, so a full diagnosis is needed.

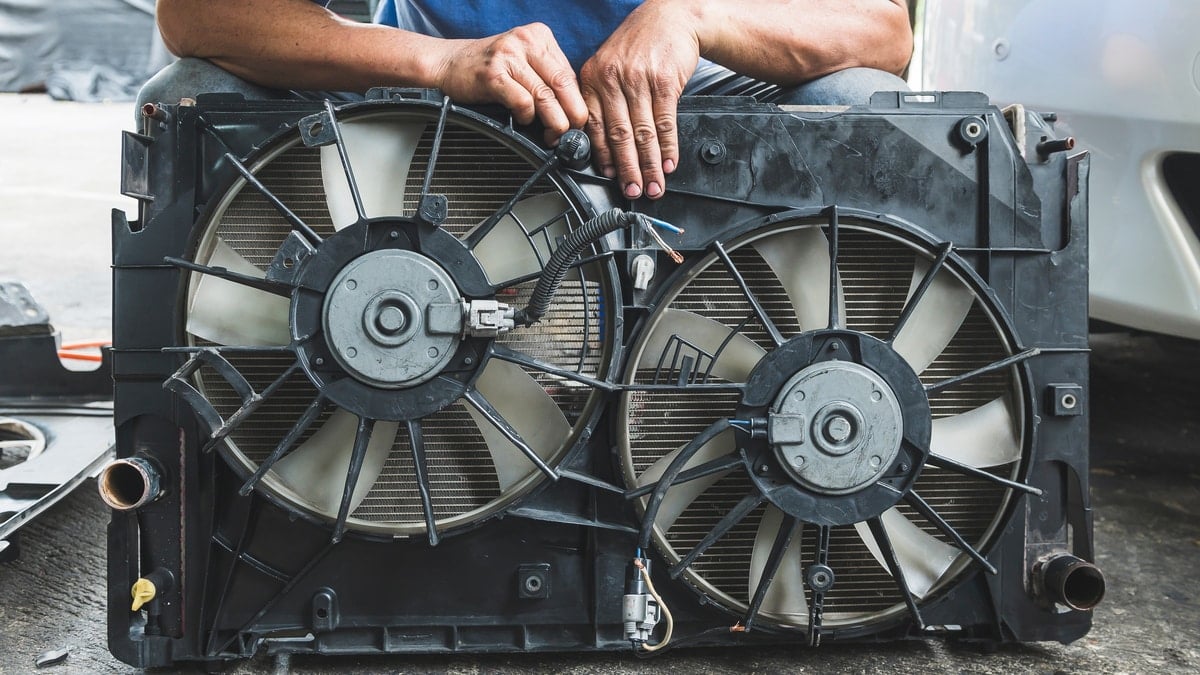

7. Overheating Engine

Possible, one of the more alarming conditions is an overheating engine. When the crankshaft pulley can’t spin the serpentine belt, the water pump may no longer function. The water pump is necessary for keeping the engine cool.

You should never ignore an overheating engine. If you allow it to continue, you could end up with a blown head gasket or cracked cylinder head, both of which force you to seek out expensive engine repairs.

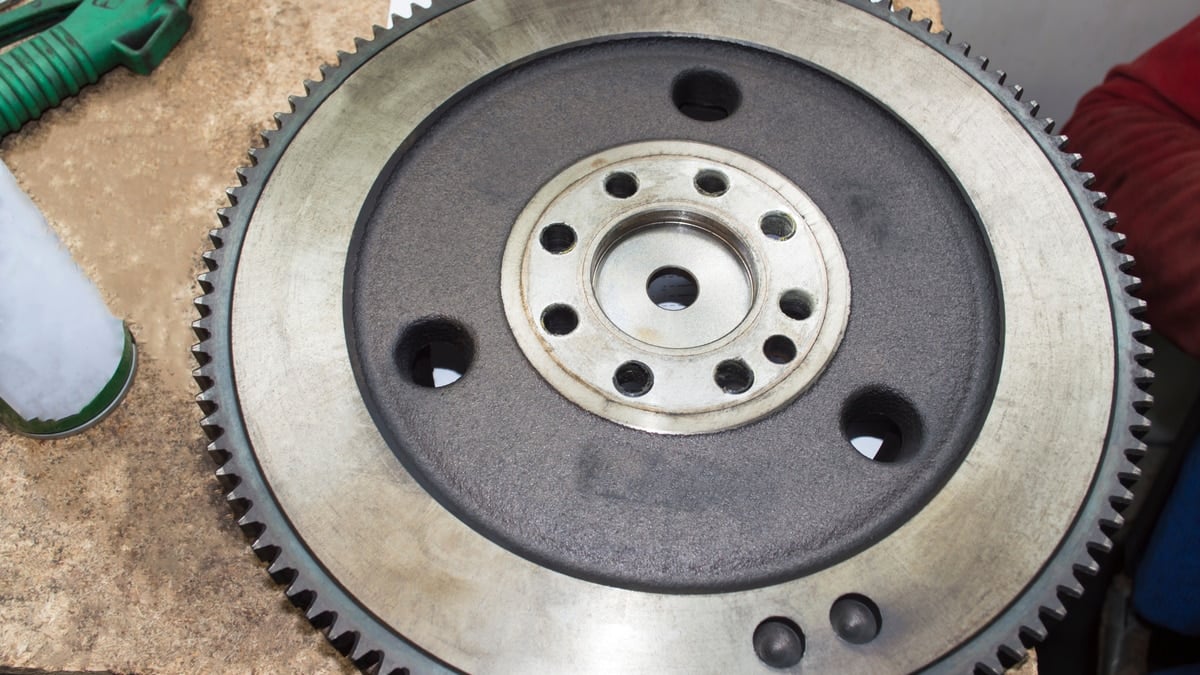

8. Damaged Transmission or Internal Engine Parts

The transmission and engine shouldn’t be damaged immediately following the crankshaft pulley or harmonic balancer failure. However, if the problem is left unchecked, you are looking at some major problems down the road. Without the dampening effect of the balancer, there are unnecessary crankshaft vibrations felt by the engine, leading to a possible broken crankshaft or worn rod bearings.

These vibrations can also lead to transmission damage. If the input shaft, gears or bearings deal with the vibrations for too long, you may start to notice fluid leaking or have trouble with shifting. Either way, transmission and engine repairs are expensive. You can prevent these from occurring by taking any crankshaft pulley failure seriously.

What’s The Function Of A Crankshaft Pulley?

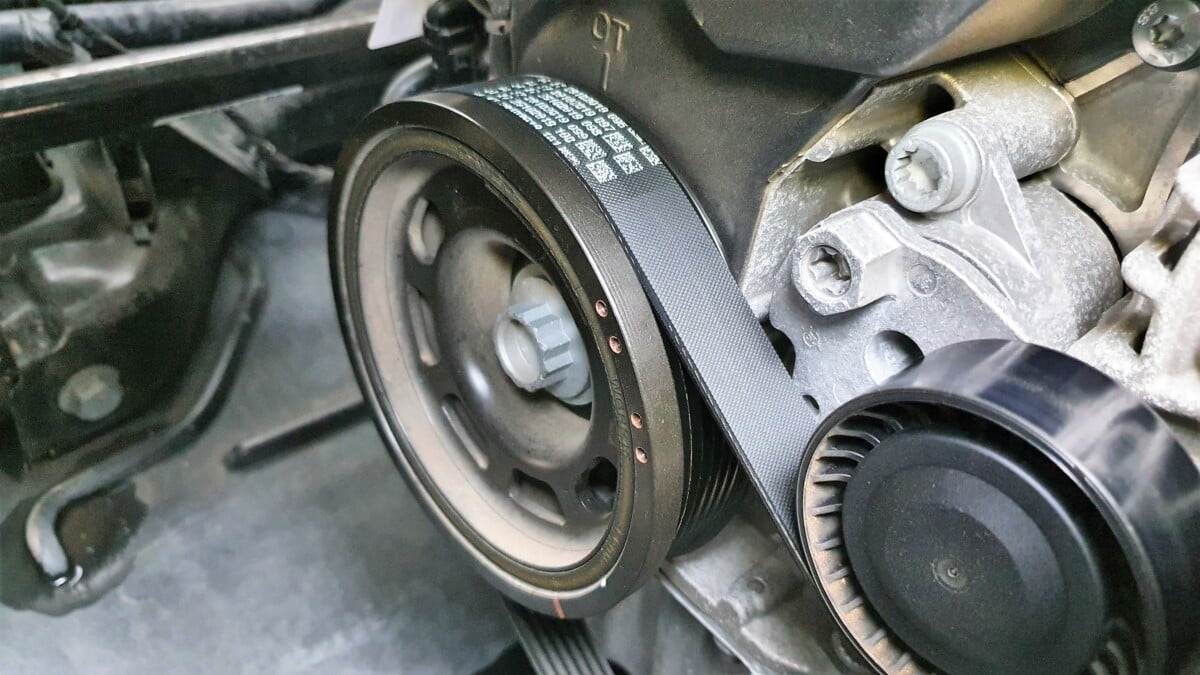

The crankshaft pulley looks like a wheel with grooves in it. It attaches to the crankshaft’s end. The crankshaft is the primary engine shaft, converting the up-and-down movement into a rotational motion. The crankshaft pulley has a few tasks that are important.

Most importantly, the pulley turns the belts on the engine, which are responsible for powering all of the accessories. Some of the accessories that are powered by this function include the alternator, power steering pump and water pump.

Typically, the crankshaft pulley is made from aluminum. However, some models use a cast iron design instead.

Attached to the crankshaft pulley is the harmonic balancer. It’s a weight that absorbs vibrations coming out of the motor, so the vital components aren’t damaged.

It contains two different parts, the inner ring that connects to the crankshaft, plus the outer ring is attached to the inner ring. Within the inner ring, there are various weights that help cancel out the vibration, while the outer ring is responsible for absorbing the remaining vibration with its rubber material.

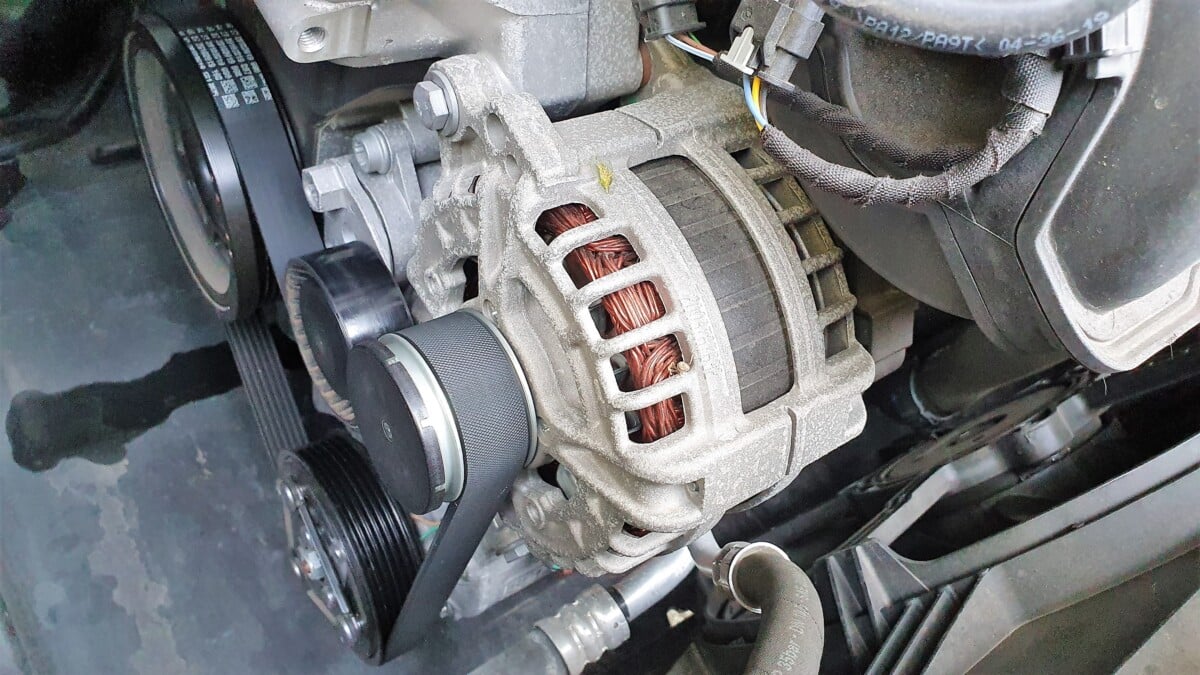

Where Is The Crankshaft Pulley Located?

The crankshaft pulley is found at the end of the crankshaft. It’s wheel-shaped and contains a groove that aligns with the key in the crankshaft. It also contains the harmonic balancer, which has various weights for absorbing vibrations.

The crankshaft converts the straight and linear motion to the pistons. However, the crankshaft pulley is designed to run other components through the belts.

How Do You Inspect The Crankshaft Pulley?

A visual inspection of the crankshaft pulley and harmonic balancer is needed if you think there could be a problem. You don’t want to put off the diagnosis because other parts could fail in the meantime.

- Look at the harmonic balancer and crankshaft pulley to see if there’s any physical damage. If you see any defect, it’s best to replace the parts.

- If nothing is seen visually, start the engine.

- Watch the harmonic balancer to see if it is wobbling while the engine is running. You may need to use a flashlight for a better view. If it’s wobbling, replace the crankshaft pulley.

- Remove the fan belt and grab the outer ring. Try to move the ring. If you can move it in and out, it’s time for a replacement.

If your inspection doesn’t reveal anything alarming or you need help with the repairs, it’s best to reach out to a professional mechanic. It’s important for these parts to work correctly to keep the engine running at its best.

How Much Does It Cost To Replace A Crankshaft Pulley?

The crankshaft pulley and harmonic balancer replacement isn’t typically an expensive job. You may spend a total of $150 to $650 for parts and labor. If you can perform the replacement on your own, the parts may only cost $20 to $400, depending on the type of vehicle you drive.

With the right tools and expertise, you could have these parts replaced in an hour or two. However, if you don’t have experience, it’s best to trust the professionals.

Can a crankshaft pulley come loose by itself?

It’s not common for the crankshaft pulley to come loose, especially when the bolts are torqued correctly. Yet, it’s possible that the crankshaft pulley will come loose over time, especially because of all of the vibration in that part of the engine. If left unrepaired, it can cause serious problems.

Can I drive with a bad crankshaft pulley?

You should stop driving when you notice that the crankshaft pulley or harmonic balancer is bad. Continuing to drive with this mechanical malfunction can lead to more serious problems or can cause you to become stranded if the car overheats or won’t start.

Can a bad pulley make a knocking noise?

Occasionally, it can cause a knocking sound. However, there are more common reasons for this noise. If you hear knocking while driving, it could be related to a bad tensioner or pulley, using the wrong octane fuel, bad timing, a lean air-fuel mixture or worn-out bearings. A complete inspection is necessary to find the cause.

What makes a crankshaft pulley go bad?

The crankshaft pulley is meant to last for the life of the engine. Yet, it endures a lot of wear and is exposed to extreme temperatures. Further exposure to engine oil or coolant because of leaks can deteriorate the pulley even faster. It’s important to make sure there’s nothing leaking when you replace the pulley and harmonic balancer to prevent the problem from occurring again.

How long does it take to replace a crankshaft pulley?

The average crankshaft pulley replacement takes between one and two hours. If you have experience with this job and the right tools, you shouldn’t need any extra time. However, if you are new at the repair, we recommend setting aside a couple more hours just in case you run into trouble.

If you are in a position where the crankshaft pulley may be damaged, it’s time to get a closer look at it. You don’t want to continue driving with a bad crankshaft pulley because it can lead to serious issues. While it may not cause a dead battery, an overheating engine or keep you from starting the car, you don’t want to take any chances.

By replacing the malfunctioning parts promptly, you prevent major engine and transmission damage. Take care of your vehicle by putting the new parts on at the first sign of trouble. It doesn’t normally cost more to fix, especially if you can do the work yourself. One thing is for sure; it’s much cheaper than installing a new engine or transmission.

Categories: Engine