No one wants to deal with engine failure, but it happens, especially if there is a bent connecting rod. This condition is also known as “throwing a rod,” or simply just a “thrown rod,” but what does it mean?

We take a closer look at the role of connecting rods inside the engine. We also examine the symptoms you might notice when the connecting rods fail and discuss the top causes of this malfunction. Let’s begin with the signs to look for.

Bent Connecting Rod Symptoms

The main symptoms of a bent connecting rod include:

- Low engine compression

- Rod knock

- Bent or Damaged Rod

- Low Oil Pressure

- Seized Engine

Here’s a more detailed list of the signs of a bent connecting rod to look for:

1. Low Engine Compression

At first, a slightly bent connecting rod might not provide any noticeable symptoms. However, as it continues to bend, it will lead to a lack of compression in that cylinder.

To determine if a bent rod is the culprit, a compression test needs to be performed. If the compression test shows that the cylinders are all within 10% of one another, there probably isn’t anything wrong with the rods. Instead, you will need to move forward with a leak test for further diagnosis.

2. Rod Knocking

The term “rod knock” is enough to get you shaking in your boots, and it should. If you hear a knocking sound from the engine while it is running, it could be an indication of trouble with the connecting rods. This repeated sound will increase in speed as the engine load becomes greater.

After a little while, the noise might disappear. This happens when the oil has circulated through the motor and caused more lubrication. Even though the sound is gone, for now, it will return the next time you start the engine if the connecting rod or bearing is to blame.

RELATED: What is Rod Knock? – Causes, Symptoms & Repair Cost

3. Bent or Damaged Rod

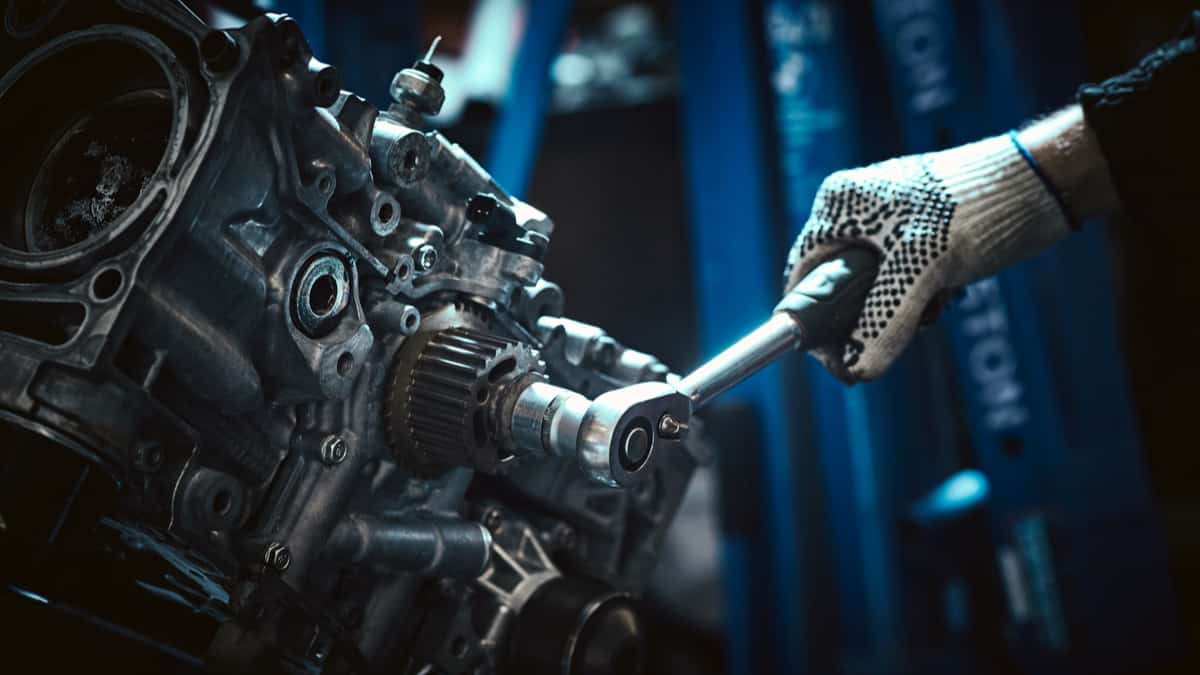

Unless you are physically inspecting the engine, this isn’t the easiest defect to notice. To visually inspect the rods, you must disassemble the engine.

However, if the engine is being worked on or it is being rebuilt, the mechanic should perform an inspection of the connecting rods. Thankfully, if there is a problem, it is much easier to replace a bent rod while the engine is already apart.

4. Low Oil Pressure

When the connecting rod goes bad or fails, the engine is going to lose oil quickly. This sudden change will alter the oil pressure. You can spot the dropping pressure on the oil gauge located on your dashboard. There may also be a warning light that comes on when the pressure drops.

You should never drive your car with low oil pressure. The lack of lubrication could cause an overheated motor, which means additional repair costs.

RELATED: 4 Symptoms of Low Oil Pressure, Causes & How to check the oil pressure

5. Seized Engine

Thrown rods are known for stalling or seizing the engine. It’s not hard to know when the engine has seized, because you won’t be able to turn it over by hand with a wrench on the crankshaft pulley bolt. In normal situations, you would be able to turn the engine by hand if it isn’t starting.

Thrown rods also create a loud banging noise or metal that flies out of the engine. This defect can lead to a huge hole in the engine block and a massive puddle of oil underneath the vehicle.

Connecting Rod Failure Causes

The most common causes of a bent connecting rod are detonation or over-revving. If you know you have been driving in deep water it could have flooded your engine, leading to hydro-lock which will easily bend your connecting rods.

Here’s a more detailed list of the causes of a bent connecting rod:

1. Flooded Engine

Air is compressible, but liquid is not. When the engine gets filled with fluid instead of air, it leads to hydro-lock.

When the engine is hydro-locked, it is at risk of a bent connecting rod at the time the vehicle starts. To ensure this doesn’t happen, you must remove the water from the engine before you turn it on.

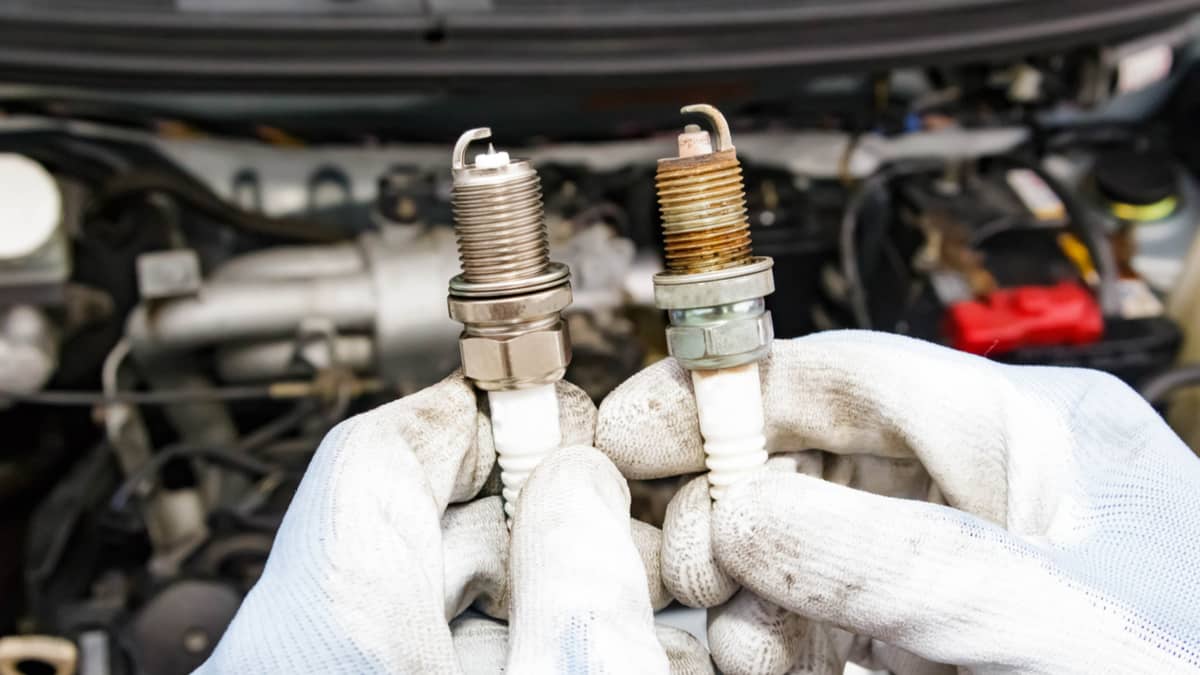

2. Pre-ignition or Detonation

These terms both indicate that combustion is occurring abnormally. The air-fuel mixture in the combustion chamber must ignite and detonate at particular intervals for reliable performance.

However, several issues lead to pre-ignition and detonation, such as using a lower octane rating fuel, carbon build-up and advanced ignition timing. Each of these events leads to cylinder pressures that are abnormal, which can cause a rod to bend or break.

RELATED: 6 Causes of a Knocking or Pinging Car Engine

3. Over Revving

When the engine revs higher, more force is exerted on the connecting rods because the pistons have increased speed. If you rev your car engine higher than it was meant to be, you could be looking at needing a replacement.

Some modern engines have safety measures built in to prevent over-revving. As you move beyond the redline, fuel might be cut to prevent damage.

In many cases, this damage occurs with manual transmission vehicles that don’t have fail-safes. When you downshift into a gear that’s too low, you might force the RPMs to rise too high, leading to catastrophic failure.

4. Adding Modifications

If you are adding engine optimizers or other parts to your vehicle, you might need to perform a tuning to keep the engine running right. Otherwise, you are pushing the engine beyond what its limits are, which might cause a thrown rod.

Additionally, extra care should be taken when you install a new intake, boost controller, turbo or exhaust. You must account for this new hardware and properly tune the engine if you don’t want to damage the connecting rods.

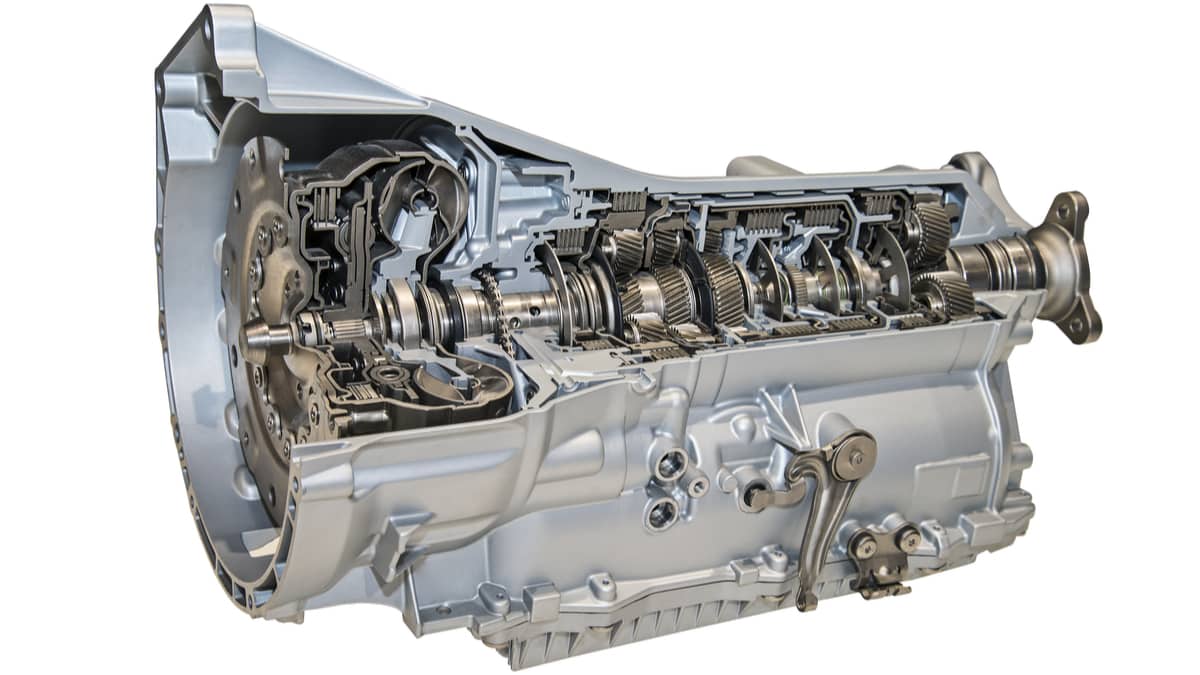

Connecting Rod Location

The connecting rod is an integral part of the internal combustion engine. It is mounted to the crankshaft and connected with a bearing.

A connecting rod bearing cap is found bolted to the large end. Most connecting rods are hollow and can be constructed of several materials, including micro-alloyed steel, high-grade aluminum, sintered metals or titanium and CFRP.

The Function

The connecting rod is responsible for creating a linkage between the crankshaft and piston where it can transmit power. These rods convert linear up and down motion from the piston into the circular movement of the car’s crankshaft.

The connecting rod contains bearings sitting between the crankshaft and the rod. These bearings prevent metal from rubbing against metal, and ensure proper lubrication while the crankshaft rotates.

There is also a pin connecting the top of the connecting rod to the piston. This pin is often referred to as the gudgeon pin, piston pin or wrist pin.

Connecting rods endure a lot of stress and tension, which leads to increased weakness. If it becomes weak, it won’t be able to handle the pressure from combustion and could break or bend. This defect leads to engine failure because the damaged connecting rod causes trouble with the power strokes, compression strokes, exhaust strokes and intake strokes.

Connecting Rods Replacement Cost

Replacing a bent connecting rod will cost $3,000 or more for parts and labor. However, some vehicles are going to require a complete engine replacement, especially if it has a thrown connecting rod. Additionally, the cost to repair luxury cars and larger models can sometimes reach $5,000 or more.

Categories: Engine