Even if you don’t know what the motor mount is, you know it has an important job, just from the sound of it. However, it’s vital to know the symptoms of a bad motor mount because this is something that should be fixed immediately.

In this guide, we look closer at the top bad motor mount symptoms and discuss what the purpose of this part is. We also evaluate the location of the motor mount, discuss how to test it and look at the average replacement costs.

Symptoms Of A Bad Motor Mount

When the motor mount goes bad, you can expect more noise coming from the engine area. You may also experience excessive vibrations, added engine movement and a jumping engine while idling. Additionally, you may notice the engine starts to tilt or looks misaligned as the mounts fail.

Here are the top five symptoms to consider.

1. Excessive Noise From Engine

The first time you hear the notorious clunking or banging that occurs from mount failure, you are likely to be extremely alarmed. In some cases, it can sound like the engine is about to break loose and fall out of the vehicle.

However, the engine shouldn’t go anywhere if only one mount is broken. Instead, the noise you hear is coming from the engine moving around in the bay and hitting other components.

2. Violent Vibrations

Another common symptom of a bad engine mount is increased vibration while driving. Whenever a mount becomes damaged, the properties that reduce vibration are diminished as well.

Part of the reason for the sound discussed above is because of these insane vibrations. If left to make these movements for long, further damage can occur to the engine and the parts around it, so don’t neglect this issue.

3. Unnecessary Engine Movement

In addition to the vibrations, there will be further movements you notice. The motor may start to lurch forward, especially when you first step on the gas. Once you get moving, the engine may resume the typical vibrations instead. You may also experience the bigger movement when you first shut off the engine.

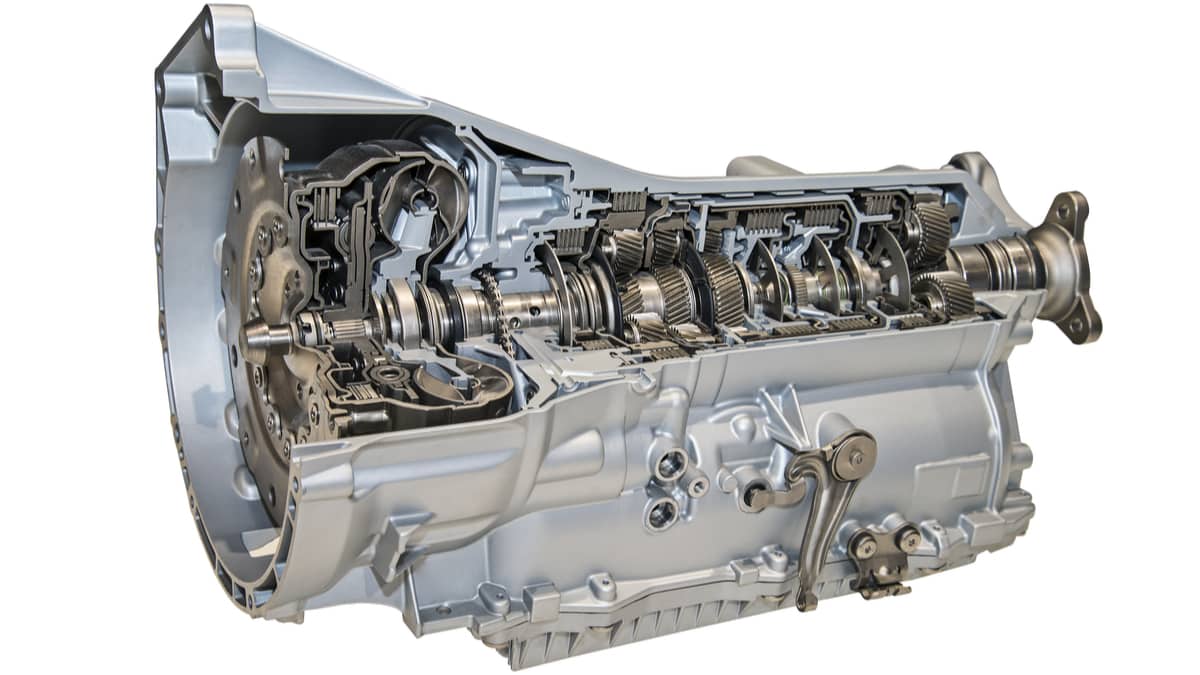

Furthermore, the engine may move more when the transmission shifts gears because of the excessive force put on it. This noticeable jolt is going to scare many drivers at first, but you never really get used to it. If the engine isn’t running smoothly, it’s time to have it looked at before bigger problems occur.

4. Tilted Engine

Because the motor mount is responsible for holding the engine in place, you can expect the motor to become misaligned if one breaks. If you look at the engine and see that it doesn’t seem to be in the right place or facing exactly where it should be, one or more of the motor mounts may be the problem.

Even worse, if multiple mounts fail, you can notice larger visible signs. The entire engine can start to sag in the bay.

As you look at the motor mounts, you may also notice physical damage to the surface. There could be corrosion, warping or cracks present. The rubber component could also start to flake and crack. Because the motor mount needs to have a solid construction and shape to support the engine, any of these defects could be considered serious.

5. Engine Jumps At Idle

One final symptom is when the engine jumps at idle. It’s similar to some of the other movements that the engine can make, but this one is most noticeable while the motor is running, but you aren’t going anywhere.

At first, you may think that the vehicle has a rough idle, such as when there’s a failing sensor or a bad spark plug. However, after closer examination, you will see that the idle itself isn’t acting erratically, it just feels that way.

What’s The Function Of A Motor Mount?

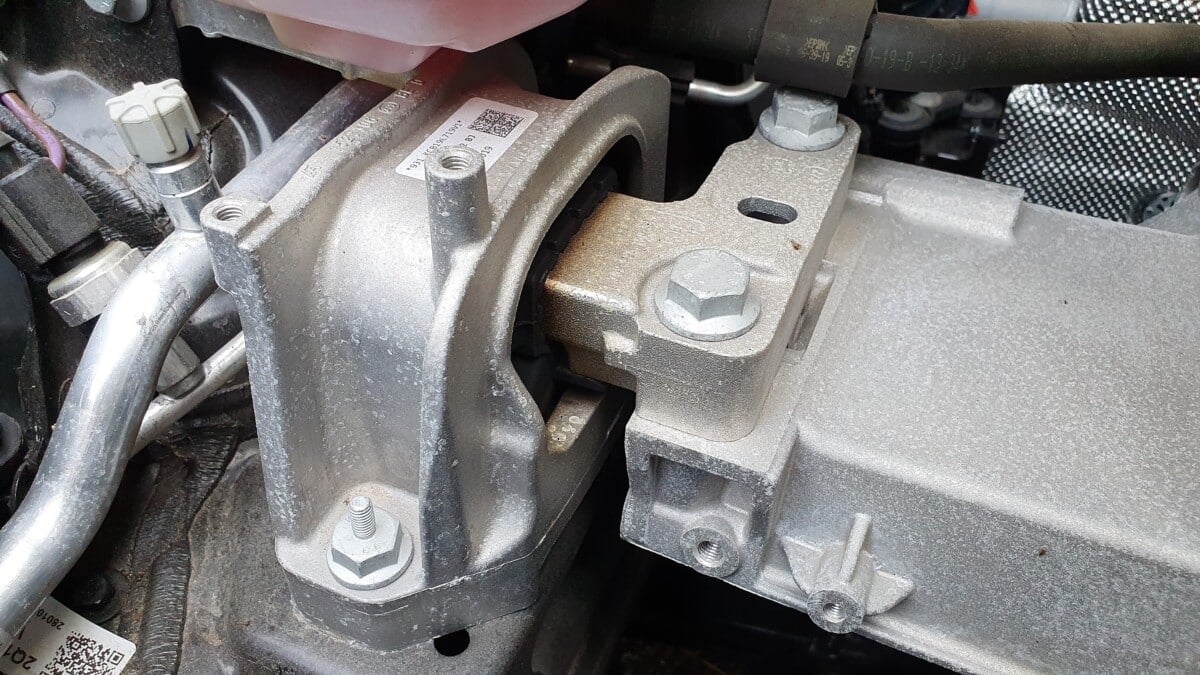

The engine mount is made to hold the motor in place within the bay. The mounts ensure that the engine isn’t sitting on any type of slope and that it doesn’t endure any unnecessary movement during operation.

Engine mounts can have a different style based on the type of vehicle it is installed in. However, there are some features that all motor mounts have, no matter what car you drive.

For starters, there should be a rubber isolator located on the mount. There’s also a bolt that holds the engine to the motor mount. Furthermore, the mount is affixed to a certain structural support to hold it in place.

When the mounts work as designed, the engine isn’t going to move excessively. Because of where the engine is located in the car, many other parts surround it and could cause vibration if it isn’t held still.

Where Are The Motor Mounts Located?

The motor mounts are installed directly to the engine. It bolts in place and then is attached to the structure of the car. Some engines use two to three motor mounts, depending on how much power it has and how it needs to be secured. In comparison, the majority of transmissions only use one mount.

How does a car manufacturer decide how many motor mounts should be used? The design is carefully determined by automotive engineers that look at what’s needed for the application. Some of the variables they consider include the weight of the engine, the orientation that it sits in and what type of mount is going to be used.

You can learn more by reading your service manual. It should outline where each of the motor mounts is located, so you can find them easily.

How Do You Test A Motor Mount?

Most people don’t regularly check the motor mounts unless there is a problem. It’s not a part that is looked at often during a routine inspection or regular maintenance. It won’t be until there’s a problem that someone thinks to check the motor mounts.

If the engine is noisier or you are experiencing any of the above signs, it’s time to take a look at the motor mounts. Thankfully, this diagnosis simply requires a physical inspection and no special tools are required.

- Inspect the motor mounts for cracks or damage.

- Look at the brackets to see if they are damaged or loose.

- If a bolt is missing, you need to secure the mount.

- Some mounts include fluid inside. Hydro motor mounts need to be checked for any leaks as well.

- Use a pry bar to see if there’s any play in the mounts or to check for separation.

It’s wise to perform a physical inspection of the mounts any time you are working on the engine for other reasons. This way, you may be able to head off a problem before it becomes an issue.

Beyond the physical inspection, you can also check the mounts this way.

- Start the car.

- Put the transmission into Drive, but keep your foot securely planted on the brake pedal.

- Apply a small amount of gas to the vehicle without letting off of the brake.

- If there’s excessive movement during this time, one or more of the mounts may be broken or loose.

When you are working around the engine, make sure you have it turned off. There are a lot of moving parts underneath the hood and you don’t want to get caught in any of them.

How Much Does It Cost To Replace A Motor Mount?

Expect to pay an average of $200 to $650 to have one engine mount replaced. Parts might make up $25 to $150 of the cost, while the other $175 to $500 could be for the labor. If you need to have more than one replaced, the cost will go up accordingly. With some vehicles, where the mounts are harder to get to, you could spend even more.

When it comes to figuring out a replacement cost, there are several variables to consider. First, you have the make and model, which can affect both the parts cost and the labor cost. Additionally, you need to think about the hourly labor rate for the mechanic installing the mounts.

If you prefer to do your own work, you may be able to replace the motor mount on your own. However, you need to support the engine at all times during the replacement. Weight must be removed from the mount, so it can be removed. You won’t be able to unbolt it with the full load on it.

While you can use a floor jack with a piece of wood on it to support the engine, it’s not a recommended practice unless you know what you are doing. Instead, you may feel better hiring a certified mechanic to do the job.

Is it OK to drive with bad motor mounts?

No, you shouldn’t continue driving with a motor mount bad. The excessive vibration of the engine can lead to serious damage, which will cost you much more to fix in the long run. Instead, you want to have the mounts looked at as soon as they create any noise or cause more vibrations.

What do bad motor mounts sound like?

When the motor mounts start to fail or become loose, the engine is able to move around in the bay. Therefore, you may hear banging and clunking, especially when you attempt to go because the engine will shift. These noises can be loud and alarming, so have them looked at immediately.

Can bad motor mounts cause shaking while driving?

Yes, a loose motor mount can lead to shaking as the engine vibrates in the bay. However, there are many things that can cause shaking, especially while driving. You want to have the car inspected, paying careful attention to not only the motor mounts but also the suspension components.

Is replacing engine mounts a big job?

It’s not normally difficult to replace engine mounts because they are typically easy to access. However, you won’t be able to unbolt the mount until you support the weight of the engine, which requires a floor jack. If you aren’t sure what you are doing, it’s best to hire a professional.

How long can I drive with a bad engine mount?

You shouldn’t continue driving at all once you know the engine mount is bad. While it is loose or broken, it allows the engine to move around unnecessarily. This movement can lead to serious engine damage, so it should never be taken lightly.

There may come a time when you have to deal with broken motor mounts. Because the noise and vibration might be severe, you will likely jump at the chance to have them replaced. Once they are replaced, you will be able to enjoy the vibration-free and noise-free drive again.

While there are many repairs you can put off for a short time, this isn’t one of them. Have the mounts replaced to ensure the engine lasts as long as possible.

Categories: Engine