The manual transmission car is not as common as it once was, but there are still some on the road today. As part of the clutch pedal, there’s a throw-out bearing that can go bad.

Because this vital part is responsible for pushing against the pressure plate to disengage the clutch, it’s critical to know the signs to look for. So, what are the symptoms of a bad throw-out bearing?

When the throw-out bearing fails, you’ll hear strange noises, such as rattling or grinding. You may also notice additional vibrations in the clutch pedal and have trouble shifting the gears. There’s also a chance for a stiffer clutch pedal during this time.

Throughout this guide, we look more in-depth into what happens when the throw-out bearing goes bad. We also evaluate the function and location of this bearing before discussing its replacement cost. At the end of our guide, you’ll find a section answering your most-asked questions.

Symptoms Of A Bad Throw-Out Bearing

1. Noise When Depressing the Clutch

When you press or release the clutch pedal, it should operate seamlessly without making any noise. As the bearing goes bad, there’s more play. This additional play leads to excessive noise.

At first, it may sound like a rattling sound. What’s most disturbing is that the sound appears to be coming from the transmission, which can cause issues when troubleshooting. You’ll know it’s coming from the throw-out bearing because the sound changes when pushing and releasing the clutch.

2. Clutch Pedal Vibrations

The throw-out bearing is meant to be perfectly aligned with the pressure plate. When it’s not, vibrations are going to occur.

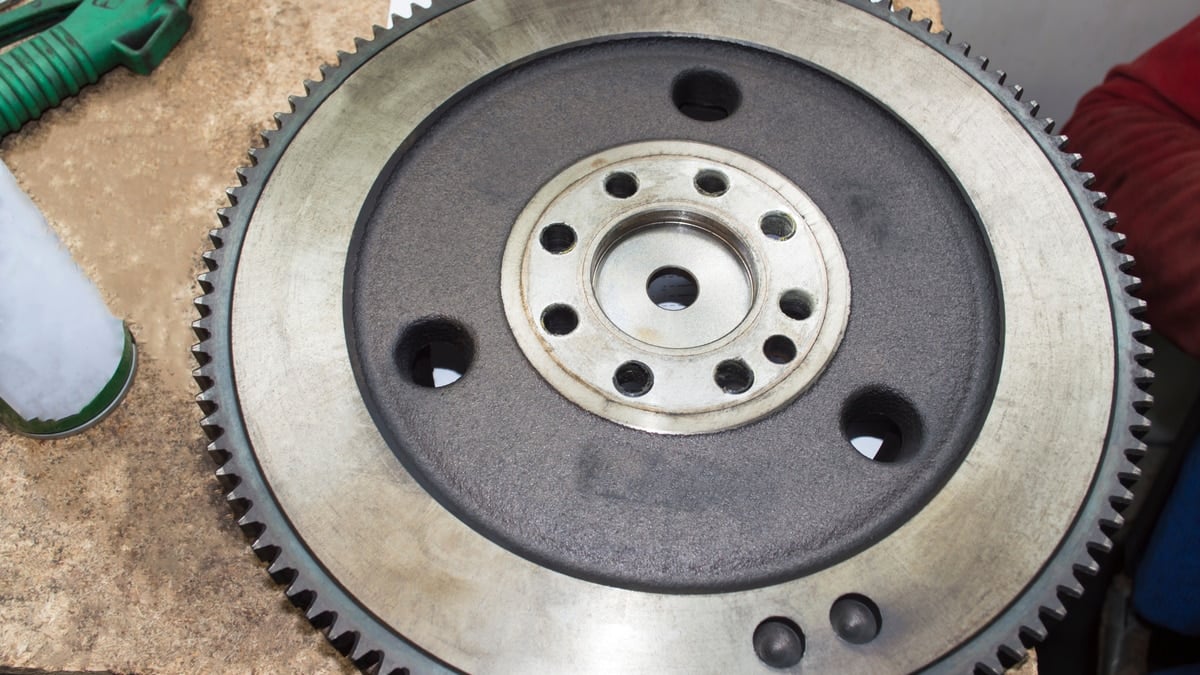

Along with the noise, you may feel these vibrations as you push on the clutch pedal. However, a bad clutch disc or flywheel can cause the same types of vibration, making it more difficult to diagnose.

3. Difficulty Shifting Gears

When you shift gears, it should be smooth and unencumbered. Yet, when the throw-out bearing fails, the shifting starts to feel stiffer or begins lagging.

Thankfully, the other symptoms generally occur first to give you some warning. For example, there should be vibration of the pedal and some noise as the throw-out bearing starts to go bad.

4. Stiff Clutch Pedal

The clutch release bearing contains unique lubrication properties to ensure operation remains smooth at all times. However, as the bearing wears down, the lubrication properties begin to suffer.

The more wear it endures, the harder the clutch pedal becomes as a result. Eventually, it could get bad enough that you wouldn’t be able to disengage the clutch. If this happens, you will need to wait for a tow truck because it would be impossible to shift gears.

RELATED: 7 Symptoms of a Worn or Bad Clutch

5. Grinding Noise When Shifting Gears

If you’ve driven a stick shift for any amount of time, you have probably heard the gears grind at some point. Yet, most gear grinding is a result of human error. The trouble is that when you hear the grinding sound and you aren’t doing anything wrong.

When grinding occurs after the clutch is completely depressed, the throw-out bearing may be to blame. At first, you may be able to get over this grinding, but you shouldn’t keep ignoring it.

What’s The Function Of A Throw-Out Bearing?

The throw-out bearing is part of the clutch system in a manual transmission car. It’s needed to disengage the car engine from the drivetrain while shifting gears. When you push down on the clutch pedal, the throw-out bearing moves closer to the flywheel.

With this action, the release fingers on the pressure plate move closer to the inside, causing them to push on the spring. This action disconnects the engine from the wheels, so you can shift gears.

Once you are done shifting and you release the clutch pedal, the throw-out bearing moves back to the original position. With this movement, the transmission and engine are connected once again.

Where Is The Throw-Out Bearing Located?

The throw-out bearing is a crucial part of the clutch system in manual transmission cars. It’s also known as the clutch release bearing. This bearing can be found between the pressure plate fingers and clutch fork.

The assembly is attached to the clutch fork, which is connected to the transmission, so it’s not always easy to access. For that reason, diagnosis of the bearing can be difficult, as discussed in more detail below.

How Do You Diagnose A Throw-Out Bearing?

Unless you feel like removing the transmission, it’s very difficult to confirm that the throw-out bearing is bad. Instead, you must pay close attention to the symptoms to determine if it’s time to replace the bearing.

Because it’s not cheap to change the throw-out bearing, it’s important that you keep this part in optimal working order. Here are a few tips to ensure that the throw-out bearing doesn’t fail prematurely.

- Change the way you drive. Don’t make unnecessary stops, reckless starts or drive with one foot on the clutch. These habits can damage the clutch and the components in the system.

- Decrease the amount of time the clutch is depressed. It’s important not to overuse the clutch. For example, if you are stopping at a red light, shift the car into Neutral so you can take your foot off of the clutch. Not only will this save the throw-out bearing, but it also allows your foot to rest.

- Inspect and maintain the clutch. With any automotive system, the clutch assembly should be maintained and inspected. By paying attention to symptoms and keeping the manual transmission system in good condition, you can head off problems before they occur.

If you aren’t sure how to care for a manual transmission vehicle, it’s best to establish a relationship with a qualified mechanic.

How Much Does It Cost To Replace A Throw-Out Bearing?

On average, expect to spend $400 to $1,500 to replace the throw-out bearing, with the majority of that cost going toward labor. The part alone doesn’t cost much, especially if you purchase an aftermarket throw-out bearing, costing between $10 and $30. However, the job is complicated and it requires advanced expertise.

There’s a chance you could perform the replacement yourself if you know how to remove the transmission and have the equipment to get it done. When performing the job on your own, it may be better to replace the entire clutch to prevent paying twice for the transmission to be removed if the clutch fails later.

To perform the throw-out bearing replacement on your own, here are some basic steps to follow. You can also get detailed information from your vehicle’s service manual.

- Raise the vehicle to allow room to remove the transmission.

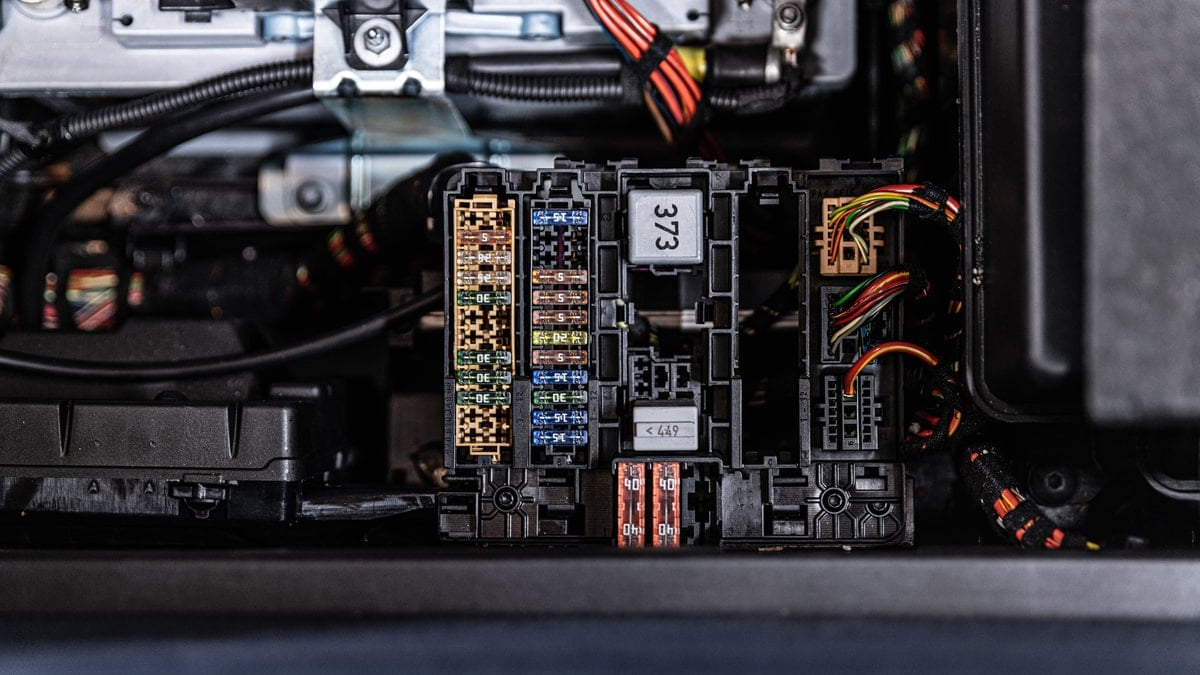

- Disconnect the battery.

- Remove the CV axles or driveshaft.

- While bracing the engine and resting the transmission on a jack, make sure the straps are securely attached to prevent the transmission from falling.

- Remove the bolts and separate the trans from the engine.

- Loosen the mounting bolts from the pressure plate in a crisscross pattern.

- While the clutch disc remains supported, take out the remainder of the bolts.

- Remove the pressure plate. Examine it for any damage.

- Check the flywheel for any signs of damage. The surface should be smooth and the teeth intact.

- While you have it apart, apply moly-based grease to the input shaft.

- Remove the cover on the withdrawal lever.

- Detach the clip assembly on the ball pivot.

- Remove the throw-out bearing and replace it with your new one.

Once this is completed, you need to put the transmission and its pieces back together again in reverse order.

If you aren’t sure you can complete these steps on your own, it’s best not to start the project. Once you rip the transmission out and take the clutch apart, you would need to get it all put back together again to move the car. If you get stuck in the middle of the project, you would need to have the vehicle towed to a service center, which only adds more money to the cost.

What does it sound like when a throw-out bearing goes bad?

At first, you may hear a rattling sound. This noise can be difficult to discern as it sounds like an internal transmission issue. Over time, the bad throw-out bearing can create a grinding noise while shifting. At this point, you wouldn’t want to wait any longer to have the bearing replaced.

Can you drive with a bad throw-out bearing?

No, it’s not safe to continue driving with a bad throw-out bearing. At best, you may end up with other damage to the clutch and transmission. The worst-case scenario is that the car no longer shifts right and you cause an accident. Either way, these are problems that could have been prevented.

What happens if you don’t fix a bad throwout bearing?

The throw-out bearing is a vital part of the clutch system in a manual transmission. For you to shift smoothly, this bearing must be in good working order. As it fails, you may hear strange noises, notice clutch pedal vibration, have trouble shifting or feel a stiff pedal. Eventually, the car may not shift at all.

How long can you drive with a bad throw-out bearing?

Once you know that the throw-out bearing is bad, you don’t have a lot of time. The bearing will seize up and ruin the clutch or the area where the transmission rides. It could also cause damage or the clutch fork or hydraulic actuating device. Do yourself a favor and have it replaced at the first sign of trouble.

Can you just replace the throw-out bearing?

You could replace the throw-out bearing by itself, but that doesn’t usually make sense. While you have the transmission pulled out for the repair, you may as well replace other parts that go bad occasionally, such as the clutch, pressure plate and pilot bushing. For many vehicles, you can purchase one kit that includes all of the necessary parts.

The throw-out bearing may not be a part that you regularly think about until it starts to fail. Yet, this small part can have dramatic ramifications for your manual transmission. If you want to continue shifting smoothly and experience a noise-free drive, it’s critical to replace the bad bearing immediately.

Unfortunately, this is a job that’s only meant for experienced mechanics. Unless you have the equipment and skill necessary to remove a transmission in your home garage, you shouldn’t attempt this repair. The damage that could be created by failing to support the transmission is not worth the risk.

Categories: Transmission