The secondary air injection (SAI) pump isn’t a part that’s regularly talked about, but it still has a valuable purpose. For that reason, you want to know the symptoms of a bad secondary air injection pump.

In this guide, we cover the top problems created by a failing secondary air injection pump and look at its purpose. We also examine where it’s located, determine the best way to troubleshoot a bad secondary air injection pump and discuss the average replacement cost. Once we get through those steps, we take a few minutes to answer some of your top questions about this system.

Symptoms Of A Bad Secondary Air Injection Pump

When the secondary air injection pump fails, you will notice the Check Engine Light. It also leads to a failed emissions test, slow acceleration and overall decreased performance. Aside from those symptoms, the idle RPM may also be slower, even to the point of stalling the engine.

Let’s jump in and see what symptoms to watch for.

1. Check Engine Light

The Check Engine Light is designed to tell you when there’s a problem with your vehicle. This indicator light may be set because of the secondary air injection pump.

With the faulty air pump affecting how the engine runs, you can expect this warning. To determine what the light is trying to tell you, it’s important to plug in your compatible code scanner. Both of these codes are common when dealing with a faulty secondary air injection pump.

- P0410: Secondary Air Injection System Malfunction

- P0411: Secondary Air Injection System Incorrect Flow Detected

Any other DTCs can be referenced in our online trouble code library.

2. Failed Emissions Test

Emissions testing is required in many states to ensure the vehicle is running efficiently. If there’s a problem with this vital pump, the hydrocarbons in your emissions system won’t be reduced correctly. Therefore, you will go to the emission testing location and probably fail.

Aside from how this robs you of your time, you want to also think about what you are doing to the environment. Continuing to drive this way means that added pollutants are entering the earth’s atmosphere.

3. Slow Acceleration

When the secondary air injection pump causes problems, the air-fuel ratio in the combustion engine becomes unbalanced. If the ratio becomes lean, it won’t get enough fuel. Therefore, you will have trouble getting the car to accelerate when you push the pedal down.

Other mechanical issues are known for creating poor acceleration as well, so you can’t rely on this symptom alone to make a diagnosis. If you combine this symptom with good troubleshooting, you should be able to figure it out quickly.

4. Rough Engine Performance

Additional engine performance problems are sure to manifest at the same time. Because of the malfunctioning pump, there will be reduced output from the engine as it tries to compensate for the issues. What you are left with is a rough performance.

The problems could get worse over time. For this reason, you won’t want to keep driving for fear of dealing with a stalling engine, which we will talk more about in the next symptom.

5. Low Idle RPM

A normal car engine idle should be between 600 and 1,000 RPMs. When the car is in this sweet spot, it means the engine is getting just the right amount of air and fuel. Yet, when this secondary air injection pump fails, the imbalance occurs and you may see the RPMs drop suddenly.

If the idle gets too low, the engine could stall. While you should be able to get the car started again, this could lead to serious drivability concerns. Plus, you don’t want the engine to stall while you are in the middle of a congested highway.

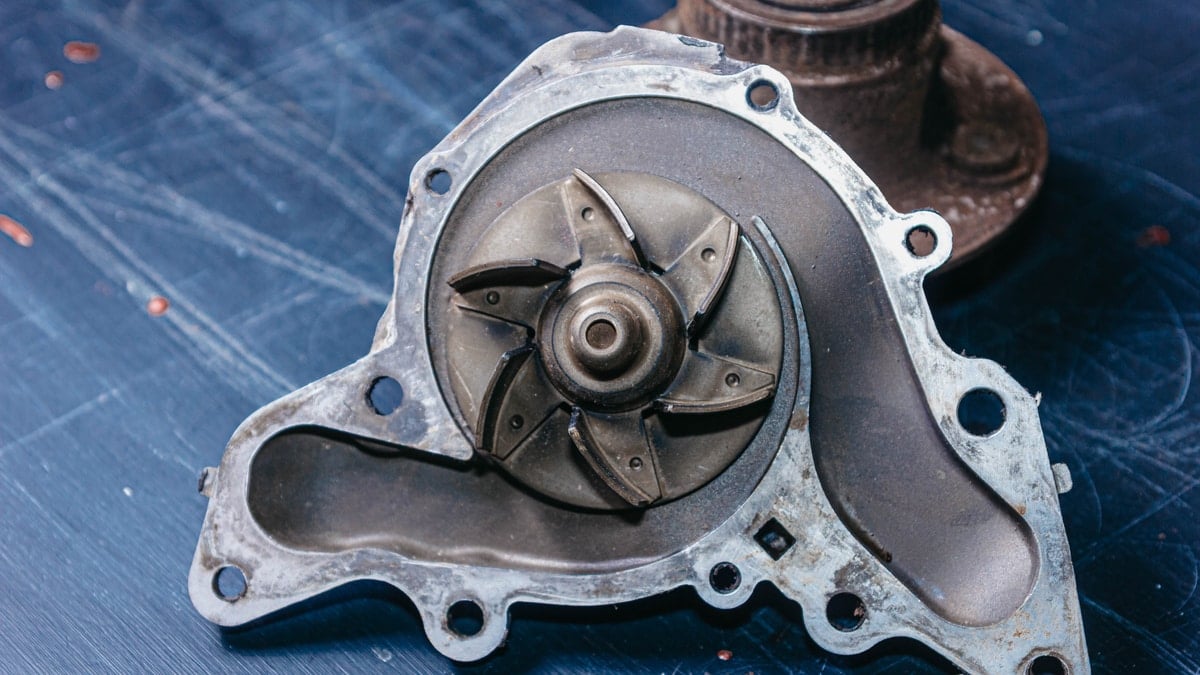

What’s The Function Of A Secondary Air Injection Pump?

The secondary air injection pump goes by several names. It can also be called the SAI pump or smog pump. This part is needed to lower how many carbon emissions are sent out of the tailpipe. Even if the engine is very efficient, it won’t always get rid of the emissions completely on its own.

Because of how the pump works, it can reduce the carbon emissions simply by pumping more air into the exhaust system. With this added air, the fumes leaving the exhaust contain fewer hydrocarbons.

Where Is The Secondary Air Injection Pump Located?

The location of the SAI pump varies based on the vehicle. It can be found underneath the hood, normally near the engine. In some vehicles, it has a serpentine belt wrapping around it.

There are other components working with the SAI pump to make up the system and reduce emissions. These parts include:

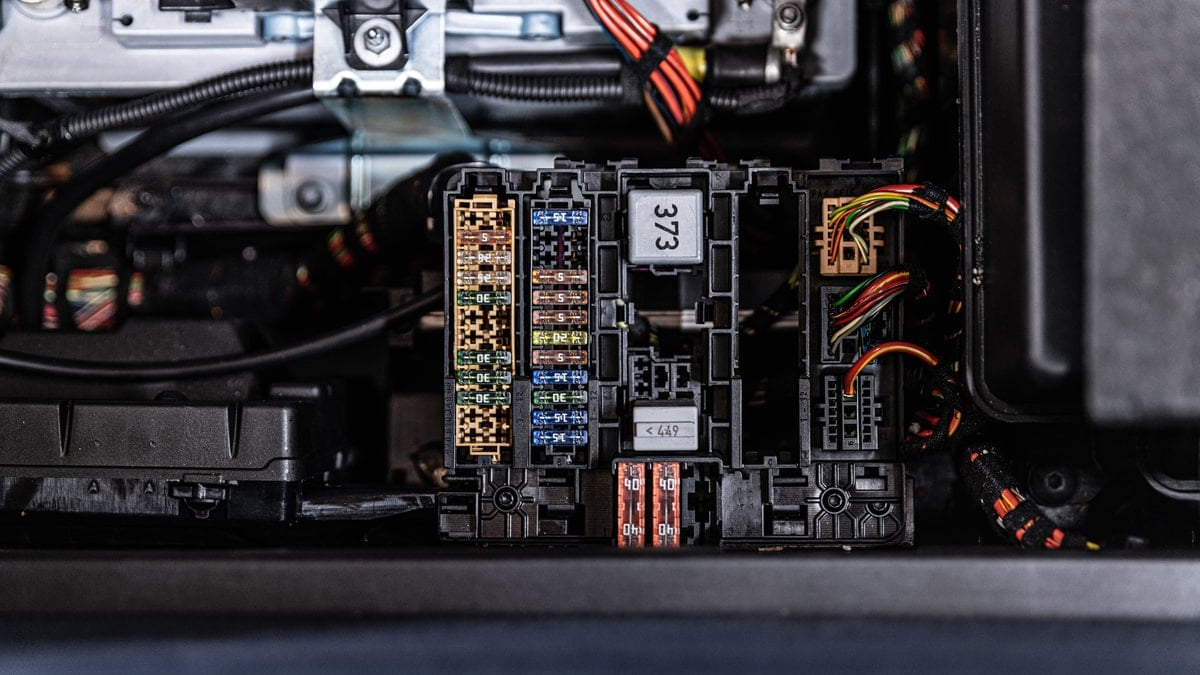

- Control relay: This is needed to regulate the electric pump. Because of the direction from the Engine Control Unit (ECU), the relay tells the pump when to operate so it can supply the right quantity of air.

- Pneumatic control valve: This part regulates the air supply in the exhaust, completing the secondary combustion.

- Combustion valve: In conjunction with the pneumatic control valve, this part prevents exhaust gases from getting into the air pump, safeguarding the functionality and preventing damage.

- Engine Control Unit (ECU): As the vehicle’s brain, this module oversees all of the operations. It coordinates the various components, determining when the activation is needed of the pump and how to adjust the parameters needed for sufficient emissions.

If you are having trouble locating your secondary air injection pump, reference a diagram in your service manual.

How Do You Test A Secondary Air Injection Pump?

If you are noticing the symptoms we’ve discussed, it’s time to check the SAI pump. Here are a few steps to consider if you want to troubleshoot on your own.

- Read trouble codes. As we described earlier, the DTCs can tell you a lot about what’s going on. Read these codes with your scanner to see if they offer any insight into the issues.

- Check the combination valve and control relay. When these parts fail, the SAI pump can overheat and stop working.

- Check for a vacuum at the control valve fitting. You should detect a vacuum once the SAI pump activates.

- If there’s a vacuum, check the control valve with your multimeter.

- Visually inspect the hose fittings to make sure nothing is loose. If you notice anything is damaged or loose, repair it.

- Check the fuel tank pressure relief valve. If this is faulty, the secondary air injection pump can fail to work properly. It could be clogged with debris, so it’s unable to function.

Some of these tests can seem overwhelming if you aren’t used to working on cars. While a service manual may provide some guidance, it may not be enough. As professionals, we would rather see you reach out for more help than continue to figure something out that’s tough to work on. Make sure you contact a local repair shop if you need more support.

How Much Does It Cost To Replace A Secondary Air Injection Pump?

On average, expect to spend $250 to $500 to have the secondary air injection pump replaced. This part is usually much cheaper to replace than the primary air pump, which could cost $500 to $800 for parts and labor.

However, the cost depends on several factors. First, you must consider the type of vehicle you drive. If you have a luxury model, such as a BMW or Mercedes-Benz, you can expect the parts to cost more than normal. Additionally, you want to think about the labor rate of your local mechanics. Some areas charge much more than others, making the prices extremely different.

If you are mechanically inclined, you may want to replace the secondary air injection pump on your own and save a few bucks. This isn’t normally a tough job and may just require you to jack up the vehicle. However, it’s important to secure the vehicle so it doesn’t fall down while you are under it.

If you plan to have a professional work on it, call around for several quotes. It also helps to get some recommendations from loved ones if you aren’t familiar with a good mechanic in the area. It’s also wise to read some online reviews and determine how other people like the service they’ve received.

Is a secondary air injection pump necessary?

Yes, it has become a necessary part of ensuring that vehicles meet strict federal emission standards. This pump is responsible for injecting clean air into the exhaust so there are fewer hydrocarbons entering the atmosphere. Without it, the vehicle wouldn’t be able to pass an emissions test.

Can I drive with a bad secondary air injection?

If you aren’t noticing any major symptoms of the bad secondary air injection pump, you may be tempted to continue driving. While you may be able to physically drive, it still isn’t a good idea. We recommend against it and encourage you to repair the car so you can do your part for the environment. It also will create a problem if you attempt to get the vehicle emission tested.

What is the life expectancy of a secondary air pump?

It’s impossible to determine how long the secondary air injection pump may last. Because this isn’t a component that’s changed as part of regular maintenance, it’s not expected to go bad often. Yet, it can fail prematurely, leaving you with a repair bill to deal with. If you notice any strange performance symptoms, have the vehicle inspected by a mechanic.

How do I know if my secondary air injection pump is bad?

When the secondary air injection pump fails, you will see the Check Engine Light on your dashboard. It also creates performance issues, such as a sluggish engine, a rough idle or poor throttle response. The other issue to be worried about is how it keeps the vehicle from passing an emissions test, which is required in many regions.

By now, you should have a better understanding of the secondary air injection pump and the purpose behind it. While it may not seem important to many drivers, this part plays an integral role in the emissions system. By helping to keep the atmosphere free from pollutants, we continue to secure our future.

If you are dealing with the symptoms we laid out, it doesn’t necessarily mean that the secondary air injection pump is to blame. The only way to know for sure would be to diagnose the system and repair the fault. Many home mechanics can handle some of the troubleshooting steps on their own, but you can also reach out to a professional for more support when needed.